- Detail

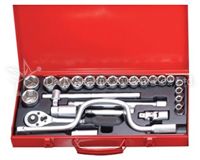

CHRME VANAIUM

| Material: | STAIN FINISH / MIRROR / WITH KNURLED |

| Contents: | DRIVE METRIC SIZE |

| 1/4"DR 50-75-100-150 MM | |

| 3/8"DR 75-150-250 MM | |

| 1/2"DR 75-125-150-250 MM |

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2025/1/8

2025 Chinese New Year Festival

Dear Sirs, By government guidelines on the Lunar New Year Festival, Daily Sealing will be closed for a vacation break from January 25 to February 02, 2025. We are very grateful for your patronage and collaboration in the past year, and would like to take

this wonderful opportunity to wish you Happy New Year of The Snake Yours truly, Daily Sealing System Co., Ltd.

MORE

2024/6/13

How to choose a vacuum sealing machine? (Chamber vacuum sealer)

In recent years, vacuum packaging has become very popular. Vacuum packaging keeps damp proof, extended shelf life, and reduced storage space. There are various types of vacuum sealing machines available on the market. How to find a suitable vacuum sealer

for your product? The following are specially divided into three categories for the vacuum sealers sold on the market (Chamber Vacuum Sealer, Non-nozzle Vacuum Sealer, and Nozzle Vacuum Sealer) to introduce advantages and disadvantages. There are other places

to pay attention to when buying, hope to help everyone buy a suitable vacuum sealer, and enhance the quality of product. ※Chamber Vacuum Sealer This is the most familiar and most commonly seen vacuum sealer. As the name suggests, it looks like a box. Therefore,

large size and heavy weight are the biggest drawbacks of this vacuum sealer, but the vacuum degree is the best compared to the other two types of vacuum sealers. We also call this vacuum sealer an internal vacuum sealer. Because the items which you want to

vacuum have to be put into the vacuum chamber in the vacuum sealer, and can be vacuum packaged. Since the vacuum item needs to be put into the vacuum chamber, the product will be limited by the size of the vacuum chamber. If the product is larger, the vacuum

chamber must be larger. As the size of the vacuum sealer increases, its price also tends to increase. Therefore, when purchasing, it needs to consider whether the internal size of the vacuum chamber is suitable for your needs. The chamber vacuum sealer is

further divided into oil-less and oil-type vacuum sealer due to the different types of vacuum pumps installed inside the machine. The vacuum capability of oil-less type vacuum sealers is slightly lower than that of oil-type vacuum sealers. Oil-less type vacuum

sealer is suitable for dry products, such as tea, dried fruit, rice, and electronic parts. The price of this vacuum sealer is lower than that of the oil-type vacuum sealer, but the vacuum capability is sufficient for dry vacuum packaging. Oil-type vacuum sealer

is suitable for both dry and moist products. If there is liquid in the product, it's recommended to choose an oil-type vacuum sealer. Suitable for packing products: meat, seafood, liquid, and powder. The Oil-type vacuum pumps installed in the Oil-type vacuum

sealers on the market have different vacuum capabilities. If you need vacuum packaging for seafood or meat products, it's recommended to choose an Oil-type vacuum sealer with better vacuum capability. If the product itself is soft, even after being vacuumed,

it will still be soft to the touch, and will not be as hard as dry products after being vacuumed. The price of Oil-type vacuum sealers is higher than that of oil-less-type vacuum sealers, and the higher the required vacuum capability, the higher the price.

Also, it should be noted, Oil-type vacuum pump needs to add vacuum oil, so when using an Oil-type vacuum sealer, it's a must to regularly check the amount of vacuum oil and the clarity of the vacuum oil. If the oil level is below the standard, vacuum oil needs

to be added; if the vacuum oil is cloudy, the old oil must be drained before adding new vacuum oil. The more often the vacuum sealer is used; the frequency of adding and draining oil is also higher. When the vacuum degree drops, you can first check whether

it is due to the vacuum oil. Some oil-type vacuum sealers will also be equipped with oil mist catchers, to capture the oil mist generated during the operation of the oil-type vacuum pump. Smoke generation was found during the operation of the vacuum sealer,

oil mist is likely generated when the oil vacuum pump is running, which is a normal phenomenon. The installation of an oil mist catcher is to reduce the situation of oil mist drifting. The oil mist catcher is a consumable, and the frequency of use will affect

its life. When purchasing a vacuum sealer, factors to consider include price, the suitable types of vacuum bags, vacuum efficiency, the size and type of products to be sealed, and the operating method. No matter what kind of product you want to vacuum, it's

recommended to bring the product to the site for testing before purchasing, test the vacuum effect and understand how to operate it, this will allow you to choose the most suitable vacuum sealer for your needs.

MORE

2024/12/6

The Magic of Vacuum Marinading: The Secret to Locking in Deliciousness

The Magic of Vacuum Marinading: The Secret to Locking in Deliciousness ◆The Principle of Vacuum Marinading Vacuum marinading reduces the air in the bag, accelerating flavor absorption. By creating a vacuum, the pressure drops, opening the food's cellular

structure for deeper marinade penetration. This method allows you to achieve marinated results in just thirty minutes compared to several hours with traditional methods. ◆Benefits of Vacuum Marinading Shortened Marinading Time: Achieve flavor infusion

in just thirty minutes. Enhanced Flavor Depth: Deeper penetration means richer flavors with less seasoning. Preservation of Freshness: Removes oxygen, reducing oxidation and retaining nutrients. Extended Shelf Life: Vacuum-sealed food lasts longer, making

it perfect for meal prep. ◆Vacuum Marinading Meat Recipe: Honey Garlic Chicken Breast *Ingredients: 2 chicken breasts 2 tablespoons honey 3 cloves garlic (minced) 50ml soy sauce ½ teaspoon black pepper 1 teaspoon rosemary *Instructions: Combine chicken,

honey, garlic, soy sauce, pepper, and rosemary in a vacuum bag. Vacuum seal and refrigerate for 30-40 minutes. Cook by pan-frying, baking, or air-frying until golden and tender. ◆Vacuum Marinading Fruit Recipe: Plum-Infused Tomatoes *Ingredients: 300 grams

cherry tomatoes 3 tablespoons plum sauce (or plum powder) 1 tablespoon lemon juice 50ml water *Instructions: Mix tomatoes with plum sauce, lemon juice, and water in a vacuum bag. Vacuum seal and refrigerate for 30 minutes. Serve directly as a refreshing snack

or salad addition. ◆Conclusion Vacuum marinading enhances efficiency and preserves the flavor and nutrition of your ingredients. It’s a quick and effective way to enjoy delicious, flavorful meals with minimal effort!

MORE

_1.jpg)

_1.jpg)

_1.jpg)

.jpg)