- Detail

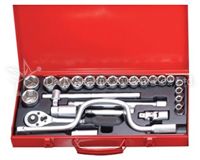

1/4"DR.61PCS SOCKET SET

| Material: | CHROME VANADIUM | ||||

| Contents: | 1-METAL CASE | ||||

| 1/4”DR | |||||

| 1- RATCHET HANDLE | |||||

| 13- SOCKETS | 4-4.5-5-5.5-6-7-8-9-10-11-12-13-14MM | ||||

| 2- EXTENSION BAR 50-100MM | |||||

| 1- BIT COUPLE 1/4"x1/4" BIT | |||||

| 1- SLIDING T-BAR | |||||

| 1- MULTI SPINNER HANLE | |||||

| 1- UNIVERSAL JOINT | |||||

| 1-MULTI ADAPTOR 3/8"Fx1/4" M | |||||

| 40-BIT 25mm | |||||

| PH:0-1-2-2-3 PZ:0-1-2-2-3 SL:2.5-3-4-4.5-5-5.5-6-6.5-7-8 | |||||

| HEX:1.5-2-2.5-3-4-5-5.5-6-7-8 | |||||

| TX:7-8-10-15-20-25-27-30-35-40 | |||||

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2024/12/6

The Magic of Vacuum Marinading: The Secret to Locking in Deliciousness

The Magic of Vacuum Marinading: The Secret to Locking in Deliciousness ◆The Principle of Vacuum Marinading Vacuum marinading reduces the air in the bag, accelerating flavor absorption. By creating a vacuum, the pressure drops, opening the food's cellular

structure for deeper marinade penetration. This method allows you to achieve marinated results in just thirty minutes compared to several hours with traditional methods. ◆Benefits of Vacuum Marinading Shortened Marinading Time: Achieve flavor infusion

in just thirty minutes. Enhanced Flavor Depth: Deeper penetration means richer flavors with less seasoning. Preservation of Freshness: Removes oxygen, reducing oxidation and retaining nutrients. Extended Shelf Life: Vacuum-sealed food lasts longer, making

it perfect for meal prep. ◆Vacuum Marinading Meat Recipe: Honey Garlic Chicken Breast *Ingredients: 2 chicken breasts 2 tablespoons honey 3 cloves garlic (minced) 50ml soy sauce ½ teaspoon black pepper 1 teaspoon rosemary *Instructions: Combine chicken,

honey, garlic, soy sauce, pepper, and rosemary in a vacuum bag. Vacuum seal and refrigerate for 30-40 minutes. Cook by pan-frying, baking, or air-frying until golden and tender. ◆Vacuum Marinading Fruit Recipe: Plum-Infused Tomatoes *Ingredients: 300 grams

cherry tomatoes 3 tablespoons plum sauce (or plum powder) 1 tablespoon lemon juice 50ml water *Instructions: Mix tomatoes with plum sauce, lemon juice, and water in a vacuum bag. Vacuum seal and refrigerate for 30 minutes. Serve directly as a refreshing snack

or salad addition. ◆Conclusion Vacuum marinading enhances efficiency and preserves the flavor and nutrition of your ingredients. It’s a quick and effective way to enjoy delicious, flavorful meals with minimal effort!

MORE

2023/9/5

What are the applications of vacuum bag packaging?

Vacuum bags have a wide range of applications, especially when used in conjunction with a vacuum sealer machine. Here are some common applications of vacuum bags: Food Storage and Preservation: One of the most common uses of vacuum bags is for storing

and preserving food items. Vacuum sealing removes air from the bag, slowing down the oxidation process and inhibiting the growth of bacteria and molds. This helps keep food fresh for longer periods, whether it's raw meats, vegetables, fruits, or pre-cooked

meals. Vacuum-sealed bags are also popular for storing leftovers and meal prep. Sous Vide Cooking: Vacuum bags are essential for sous vide cooking, a cooking method where food is placed in a vacuum-sealed bag and cooked in a precisely controlled water bath

at a consistent temperature. The vacuum-sealed bags ensure that the food is evenly cooked and retains its natural flavors and juices. Marinating: Vacuum bags can be used for marinating meats and other food items. By removing the air from the bag, the marinade

is more effectively absorbed into the food, resulting in enhanced flavors. Long-term Freezing: Vacuum-sealed bags are excellent for freezing food items. The absence of air prevents freezer burn, maintaining the quality and taste of the food even after prolonged

storage. Travel and Outdoor Activities: Vacuum bags can be used to pack clothes and other travel essentials, compressing them to save space in luggage. They are also used for storing items during camping or hiking trips to protect them from moisture and

keep them organized. Document and Jewelry Storage: Vacuum bags are useful for protecting important documents, photographs, and valuable items like jewelry from dust, moisture, and other elements that could cause damage. Organizing Household Items: Vacuum

bags can be used to store seasonal clothing, blankets, and pillows, reducing their volume for easy storage when not in use. Emergency Preparedness: Vacuum bags can be used for creating emergency kits, preserving food supplies, and organizing essential items

for disaster preparedness. Industrial and Commercial Packaging: Vacuum bags are used in various industries for packaging sensitive or perishable products, ensuring they stay fresh and intact during shipping and storage. It's essential to use vacuum bags

specifically designed for vacuum sealers to ensure proper functioning and safety. The versatility and benefits of vacuum bags make them a practical choice for various storage and preservation needs in both household and commercial settings.

MORE

.jpg)

2022/12/15

Vacuum Sealer Bag

Vacuum package have to use the vacuum sealer bags, and it can keep the vacuum effect. Daily’s vacuum sealer bags are made in Taiwan, and have SGS approval, pass BPA FREE test, FDA and EU standards. ※ Kinds of Vacuum sealer bags: - Vacuum channel Sealer

Bags / Vacuum embossed sealer bags It is suitable for non-nozzle vacuum sealers. The straight lines on the vacuum channel sealer bags will make the channels help non-nozzle vacuum sealers to vacuum the air from the bags. We have stocks of all standard sizes

of vacuum channel sealer bags. We also can produce custom-made size and printing of vacuum channel sealer bags, but it has the minimum order quantity limit. Vacuum channel sealer bags: one side is straight lines and the thickness is 0.3mm, and the other side

is flat and the thickness is 0.085mm. - Vacuum sealer bag It is suitable for nozzle type vacuum sealer and chamber vacuum sealer. We have stocks of all standard sizes of vacuum sealer bags. We also can produce custom-made size and printing of vacuum sealer

bags, but it has the minimum order quantity limit. the thickness of vacuum sealer bags is 0.08mm, and we can accept custom-made thickness, but it has the minimum order quantity limit. ※ Vacuum sealer bags material: - NY+PE: NY can block the air into the

vacuum sealer bags, so it can keep the vacuum effect. ※ Functions of vacuum sealer bags: - Keeps food safe and fresh - Simmer - Microwave-safe ※ Spec. of Vacuum sealer bags : There are two kinds of vacuum sealer bags: standard size vacuum sealer bags and

vacuum sealer roll bags. - Standard size vacuum sealer bags is already cut to the standard size. They are in stock. We also accept the order of custom-made special size and printing. - Vacuum sealer roll bags: We produce the roll bags for vacuum channel sealer

bags. The standard length of vacuum channel sealer roll bags is 10M and 20M. The size of vacuum channel sealer roll bags also can be custom-made. It is suitable for many sizes of package articles but the small quantity. More details: Click here

MORE

.jpg)

_1.jpg)

_1.jpg)

_1.jpg)