- Detail

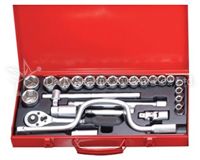

17PCS 538RG 20MM FLEXIBLE GEAR WRENCH WITH GO-THROUNG SOCKET SET(20mm)

| Material: | 1-BLOW MOLD CASE |

| Contents: | 1-538RG 20MM |

| 12-GO THROUNG SOCKET 8-910-11-12-13-14-15-16-17-18-19MM | |

| 1-20MM 75MM GO THROUNG EXTENSION BAR | |

| 1-1/4"x20mm GO THROUNG ADAPTOR | |

| 1-3/8" x20mm GO THROUNG ADAPTOR | |

| 1-1/2"x20mm GO THROUNG ADAPTOR |

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2024/6/24

Types of Vacuum Sealers

Types of Vacuum Sealers When choosing a vacuum sealer, it's important to understand the different types and features available. Vacuum sealers play a crucial role in food preservation, medical supplies packaging, and electronic products protection, among

other areas. Based on their functionality, sealing methods, and application scope, vacuum sealers can be divided into the following main types: 1. Single Chamber Vacuum Sealer: This type has one sealing chamber and is primarily used for small batch production,

suitable for sealing and vacuum processing of small items such as food packaging and medical supplie 2. Double Chamber Vacuum Sealer: Featuring two independent sealing chambers, one for vacuum processing and the other for sealing, this design significantly

increases production efficiency and is suitable for industrial-level applications that require mass production. 3. Vertical Vacuum Sealer: Designed for ease of operation with large items, such as poultry and meat, it is suitable for packaging large objects

4. Horizontal Vacuum Sealer: More suitable for small-sized items, this sealer is flexible in operation and commonly used for packaging needs in homes or small businesses. 5. Gas Flush Vacuum Sealer: Capable of injecting gas (such as nitrogen) while sealing,

it is used to extend the shelf life of products, especially in the food packaging industry. 6. Continuous Vacuum Sealer: Suitable for high-efficiency industrial production lines, it can perform sealing operations continuously and is suitable for large-scale

production requirements. 7. Manual Vacuum Sealer: Ideal for small-scale production, it is easy to operate and cost-effective, making it an ideal choice for households or small businesses. Understanding the diverse types of vacuum sealers and their specific

applications is essential for selecting the right equipment for your needs. Whether for home use, small businesses, or industrial applications, each type of vacuum sealer offers unique benefits tailored to different sealing tasks. By considering the scale

of production, the size of the items to be sealed, and any specific requirements such as gas flushing, you can make an informed decision that enhances efficiency, preserves quality, and extends the shelf life of various products. Contact us Types of Vacuum

Sealers

MORE

2024/7/5

Q&A How to make the sealing line of the impulse sealer even and beautiful?

Q&A How to make the sealing line of the impulse sealer even and beautiful? Q: Users often want to know why the sealing line is crooked and thin, rather than the flat and complete 2mm or 5mm wide sealing line tested by the manufacturer. A: The key point

is cooling time. For impulse sealers, whether hand type or foot-operated type, both the sealing and cooling time are manually controlled. In order to shorten the package time, many users will ignore the cooling time directly. As soon as the heating time is

up and the heating light goes off, they release the handle or foot pedal. This will result in uneven sealing lines. Q: How long does the cooling time need to be? A: It is recommended to refer to the sealing time. If the heating time is longer, the cooling

time should be increased accordingly, but not necessarily in a proportional manner. It still needs to be tested. Based on the experience, if using regular bags and the sealing time is not set for a long time, it is recommended that customers press for an additional

1 second after the heating light goes off (the editor usually counts to 3 in their mind) before releasing the handle or foot pedal. Q: If I don't care about the appearance of the sealing line, can I ignore the cooling time? A: It is still recommended to

have some cooling time. A complete sealing line is not only visually appealing to customers, but the most important, it ensures the bag is securely sealed. The impulse sealer uses heat to stick the bag mouth and seal it tightly, and then cools the sealing

line by pressing the bag. This is how the sealing line can be both firm and smooth. Without cooling time to cool the sealing line, the sealing line of the bag mouth may be thin and easily melt and break, which could lead to bag rupture and increase the workload

instead.

MORE

2024/7/12

Q&A-Why can’t the vacuum effect be maintained after using the vacuum sealer?

Why can’t the vacuum effect be maintained after using the vacuum sealer? The following are possible reasons. Users can check by themselves first. 1. The wrong material of packing bags: the material of plastic bags is PE, PP which can’t maintain the vacuum

effect. The air will enter into the bags after the vacuum sealer finishing working. It is recommended to choose Nylon bags, Aluminum foil bags which can maintain the vacuum effect for a long time. 2. The sealing line is not sealed well: please check whether

the sealing line is complete or not. If the sealing line is not closed, the air will run into the bags. (1) If the bag is too thick, and the vacuum sealer wasn't set for enough sealing time, the heat wasn't enough to seal the bag. If the vacuum sealer can

adjust the sealing time, users can add more seconds to test whether the sealing is firm. If the vacuum sealer can't adjust the sealing time, users may need to replace the thinner bag or buy another vacuum sealer with setting sealing time function. (2)

There have also been cases where the bottom seal of the original bag was not sealed properly. In this case, seal the bottom sealing line again before vacuuming. 3. Vacuum bag styles are not suitable for vacuum sealers: non-nozzle vacuum sealers can't

be used for vacuum flat bags. Therefore, if you buy a non-nozzle vacuum sealer, you must pay attention to the style of the bag you use. This vacuum sealer is a must-to-use vacuum embossed bag or Nylon gusset vacuum bag. It is recommended that when purchasing

a vacuum sealing machine or vacuum bag, it is more appropriate to confirm with the supplier first. 4. The vacuum bag is broken: (1) If the package article has acute angles, be careful not to cut the vacuum bag when putting it into the vacuum bag. (2)

Vacuum sealer in the process of pumping, when the bag is shrunk to the package, it may be punctured by the packaging.

MORE

_1.jpg)

_1.jpg)

_1.jpg)

.jpg)