- Detail

1/4"DR.61PCS SOCKET SET

| Material: | CHROME VANADIUM | |||

| Contents: | 1-METAL CASE | |||

| 1/4”DR | ||||

| 1- RATCHET HANDLE | ||||

| 13- SOCKETS | 4-4.5-5-5.5-6-7-8-9-10-11-12-13-14MM | |||

| 8-DEEP SOCKET 6-7-8-9-10-11-12-13MM | ||||

| 2- EXTENSION BAR 50-100MM | ||||

| 1- BIT COUPLE 1/4"x1/4" BIT | ||||

| 1- MULTI SPINNER HANLE | ||||

| 1- UNIVERSAL JOINT | ||||

| 1-SLIDING T-BAR | ||||

| 10-BIT 25mm | ||||

| TX:7-8-10-15-20-25-27-30-35-40 | ||||

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2024/1/31

Choosing the Right Bag for Vacuum Packaging: PE Bags vs. Vacuum Bags Explained

Choosing the Right Bag for Vacuum Packaging: PE Bags vs. Vacuum Bags Explained When it comes to vacuum packaging, one common dilemma often arises: Should you opt for PE bags or vacuum bags? This question is prevalent among many, especially those new to

the realm of vacuum sealing. The choice between PE bags and vacuum bags is not just about the cost but also about the effectiveness of the vacuum seal in various applications. Understanding the Need for Vacuum Packaging The purpose behind vacuum packaging

can vary significantly. Whether it's extending the freshness of food, protecting items from rust and dust, saving space, or merely maintaining a temporary vacuum effect, the choice of bag plays a crucial role. Here, we delve into the characteristics of PE

bags versus vacuum bags to help you make an informed decision. PE Bags for Vacuum Packaging: Pros and Cons PE bags, commonly seen in the market, are known for their accessibility and affordability. However, their ability to block air is not as effective as

specialized vacuum bags. During the vacuum process, air may continue to seep into PE bags, preventing the formation of a true vacuum state. Despite this, thicker PE bags can maintain a vacuum effect for a short period. High-density PE (HDPE) bags can achieve

a vacuum state post-sealing, but the duration of this effect is uncertain. If a long-term vacuum isn't your priority, PE bags might be worth considering, though testing their effectiveness for your specific needs is recommended. Vacuum Bags: The Optimal Choice

for Long-Term Vacuum Sealing For those seeking a durable vacuum state, vacuum bags are the superior choice. Materials such as nylon (NY) and aluminum foil are particularly effective. PET bags offer another viable option, each material presenting distinct advantages

depending on the items being packaged and specific user requirements. Selecting a Vacuum Sealer and Vacuum Bags: Guidance and Recommendations Concerned about which bags are compatible with your vacuum sealer? Wondering which material best suits your needs

or whether the vacuum effect will be satisfactory? Daily Sealing is here to assist. We offer expert advice on choosing the right vacuum sealer and vacuum bags tailored to your requirements, ensuring your vacuum packaging process is as efficient and effective

as possible. Conclusion Choosing the right bag for vacuum packaging involves considering the specific needs of your packaging requirements. While PE bags may suffice for short-term or less critical applications, vacuum bags offer a more robust solution for

long-term freshness and protection. For personalized advice and solutions that cater to your vacuum packaging needs, turn to the experts at Daily Sealing. g Choosing the Right Bag for Vacuum Packaging: PE Bags vs. Vacuum Bags Explained

MORE

.jpg)

2022/12/15

Vacuum Sealer

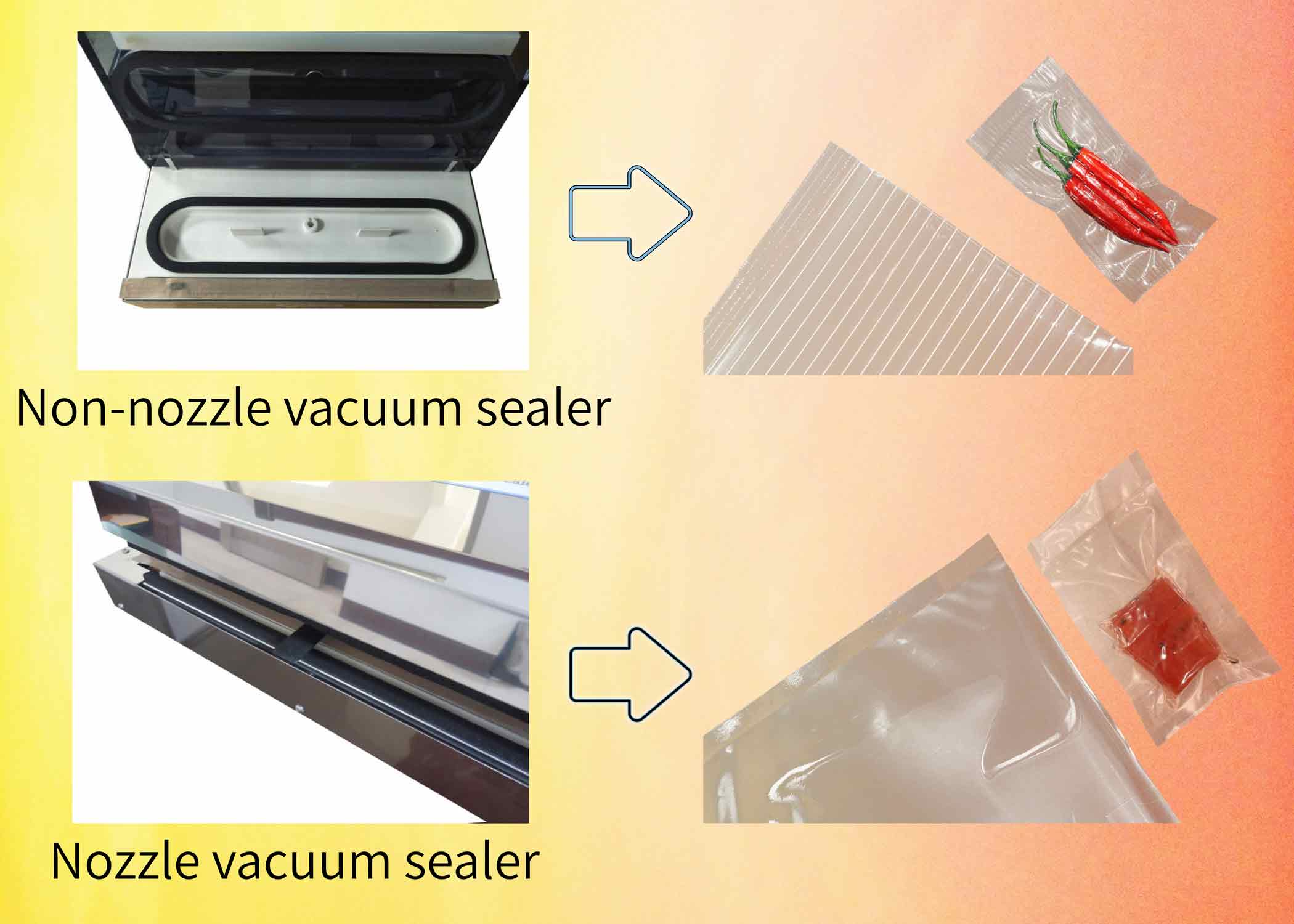

Vacuum Pack can keep fresh and preserve longer, moisture-proof and volume reduction. Daily has many kinds of vacuum sealer could be chosen. The following is the introduction of Daily vacuum sealer for your reference. ※ Vacuum sealer type: - Non-nozzle

vacuum sealer : suitable for vacuum channeled bags, nylon gusset bags and alum. gusset bags. The length of vacuum bags is not limit. - Nozzle Vacuum Sealer : suitable for vacuum bags. The length of vacuum bags is not limit. There are two type of Daily nozzle

vacuum sealer: motor control and air control. - Chamber type vacuum sealer : suitable for all kind vacuum bags. The vacuum degree of vacuum sealers is the highest. The size of vacuum bags is limited of the vacuum chamber. This vacuum sealer is suitable for

vacuuming liquid and powder. - Vacuum band sealer : there are two type vacuum band sealer could be chosen because of vacuum degree. ※ Two type Vacuum pump: - Oil-less vacuum pump : Suitable for Vacuuming dry and solid articles, such as tea leaves, rice,

beans and electronic component etc. - Oil vacuum pump : suitable for liquid and powder articles. The vacuum degree is higher than oil-less vacuum pump. It needs to change and add the vacuum oil inside the vacuum pump when the vacuum oil is dirty. ※ Vacuum

sealer application: - For food : Keep food fresh. - For other articles : Moisture-proof, anti-mildew, dust-proof, anti-rust. For example: electronic parts. - Volume reduction : fluffy articles such as bed quilt can be reduced the volume and then easy to ship

or storage. ※ Vacuum sealer accessories : - Channel Vacuum Bag : Suitable for non-nozzle vacuum sealer. There are the straight lines on Daily channel vacuum bag. - Vacuum sealer bag : Suitable for nozzle type vacuum sealer and chamber type vacuum sealer.

- Vacuum canister : Daily vacuum canister can be vacuumed by manual or used by non-nozzle vacuum sealer. - Acrylic mold : When vacuuming, it can help the article to make the square shape, such as tea and rice. -Parts-Heating Element, Teflon tape. More details: Click

here

MORE

2025/12/24

Vacuum Sealer Bags 101: Can I Reuse Them & What Bags Work with My Machine? (Vacuum Sealer

Vacuum Sealer Bags 101: Can I Reuse Them & What Bags Work with My Machine? (Vacuum Sealer Bags, Consumables) The bags you use are the most important consumables for your vacuum sealer. Understanding the different types and reuse rules can save you money

and ensure a perfect seal every time. Can I Reuse Vacuum Sealer Bags? The short answer is yes, sometimes, but with a big safety caveat. When to Reuse: If the bag contained clean, low-odor, cooked, or dry foods (like baked goods, nuts, or leftover pasta),

you can often wash, dry, and reuse the bag. Just make sure to cut the original seal cleanly and ensure the bag is completely dry before re-sealing. When NOT to Reuse (Safety First): Never reuse bags that have contained raw meat, poultry, fish, or greasy/oily

foods. Even after washing, there is a risk of cross-contamination and the residue may compromise the next seal. When in doubt, use a new bag. Which Bag Type Do You Need? The type of bag you buy depends entirely on the type of vacuum sealer you own: Vacuum

sealer embossed and channel bags (For non-nozzle type vacuum sealer): non-nozzle type vacuum sealer (the most common type, where the bag sits outside the machine) require bags with a special texture or channels inside. This texture allows the air to be successfully

drawn out of the bag and past the sealing area. Smooth Bags (For Nozzle Type Vacuum Sealer and Chamber Vacuum Sealers): Chamber vacuum sealers work by removing all air from a chamber where the bag is fully enclosed. Because of this, they can use more economical

smooth bags that lack the internal texture. Make sure you are purchasing the correct vacuum sealer bags for your machine, as using a smooth bag in a non-nozzle type vacuum sealer will result in a complete vacuum failure.

MORE

_1.jpg)

_1.jpg)

_1.jpg)

.jpg)