- Detail

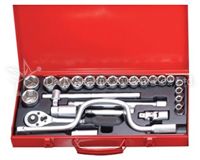

1/2"DR DEEP SOCKET 6PT&12PTY

| ITEM NO | SIZE (mm) | SIZE(SAE) | L(mm) |

| CMD4108 | 8 | 5/16" | 77 |

| CMD4109 | 9 | 11/32" | 77 |

| CMD4110 | 10 | 3/8" | 77 |

| CMD4111 | 11 | 7/16" | 77 |

| CMD4112 | 12 | 15/32" | 77 |

| CMD4113 | 13 | 1/2" | 77 |

| CMD4114 | 14 | 9/16" | 77 |

| CMD4115 | 15 | 19/32" | 77 |

| CMD4116 | 16 | 5/8" | 77 |

| CMD4117 | 17 | 21/32" | 77 |

| CMD4118 | 18 | 11/16" | 77 |

| CMD4119 | 19 | 3/4" | 77 |

| CMD4120 | 20 | 25/32" | 77 |

| CMD4121 | 21 | 13/16" | 77 |

| CMD4122 | 22 | 7/8" | 77 |

| CMD4123 | 23 | 77 | |

| CMD4124 | 24 | 15/16" | 77 |

| CMD4125 | 25 | 1" | 77 |

| CMD4126 | 26 | 1-1/16" | 77 |

| CM4127 | 27 | 77 | |

| CMD4128 | 28 | 1-1/8" | 77 |

| CMD4129 | 29 | 77 | |

| CMD4130 | 30 | 1-3/16" | 77 |

| CMD4132 | 32 | 1-1/4" | 77 |

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2024/2/23

Choosing the Right Vacuum Sealer: Universal vs. Specific Bag Models Explained

Choosing the Right Vacuum Sealer: Universal vs. Specific Bag Models Explained The main difference between universal vacuum sealers and specific bag vacuum sealers lies in their adaptability to materials and types of vacuum seal bags. These differences

directly affect the vacuum sealer's range of use, flexibility, and cost-effectiveness. Universal Vacuum Sealers Universal vacuum sealers, as the name suggests, are machines that can use vacuum seal bags of various materials and thicknesses. The main advantage

of these sealers is their versatility and flexibility. 1. Universal vacuum sealers usually have an open sealing area where users can place food or other items before starting the vacuum sealing process. 2. When using a universal vacuum sealer, there is typically

no need to choose a specific size or type of sealing bag, as they can adapt to different sizes and types of bags. 3. This type of sealer is generally more suitable for home use, as they are simpler and more convenient to operate, requiring less setup and adjustment.

4. Versatility: They can use bags of various materials, including PE, PA, PET, etc., without restrictions on the material of the sealing bag. 5. Cost-effectiveness: Since cheaper, generic bags can be used, it may be more cost-effective in the long run. 6.

Broad applicability: Suitable for packaging a wide range of needs, whether food or non-food items. Specific Bag Sealers Specific bag sealers are machines that can only use vacuum seal bags of a particular material or brand. These sealers are often designed

for special bag materials or specific sealing needs. 1. Specific bag vacuum sealers require the use of particular sizes and types of sealing bags. Before use, users need to place food or other items into the sealing bag, then insert the bag's opening into

the sealer for sealing. 2. This type of sealer typically offers more sealing options, such as different sizes of sealing bags, wet and dry sealing, etc. 3. Specific bag vacuum sealers are generally more suitable for commercial use or situations requiring a

lot of sealing, as they can provide higher efficiency and more options. 4. Specialization: Requires the use of specific materials or brands of bags, which are usually designed to fit the machine's sealing method. 5. Cost: The cost of specialized bags is generally

higher than that of generic bags, which may increase the long-term cost of use. 6. Quality control: Using specialized bags may result in better quality control and sealing effects, as the machine and bags are designed as an integrated system. Considerations

for Choosing Between Universal and Specific Bag Vacuum Sealers 1. Cost: Consider the initial investment and the long-term cost of use. 2. Usage needs: Choose a more flexible universal vacuum sealer if your sealing needs involve frequently changing bag types,

or a specific bag sealer if you have higher requirements for sealing quality. 3. Convenience of operation: Universal vacuum sealers are generally simpler and more convenient to operate, as they have less strict requirements for the bags. In summary, choosing

between a universal vacuum sealer or a specific bag vacuum sealer should be based on your sealing needs, budget, and quality requirements. If you need higher flexibility and cost-effectiveness, a universal model may be a better choice; if you have higher requirements

for sealing effects and do not mind the cost of specialized bags, then a specific bag model may be more suitable. g Choosing the Right Vacuum Sealer: Universal vs. Specific Bag Models Explained

MORE

.png)

2024/6/21

FAQs (Frequently Asked Questions) about vacuum packaging

FAQs (Frequently Asked Questions) about vacuum packaging Vacuum packaging is currently a trend, and recently, many users have purchased vacuum sealers or vacuum bags, generating a lot of questions. Here are answers to the most commonly asked questions:

1. Which vacuum sealer is suitable for me? A: There are many vacuum sealers on the market, and it is not easy to choose a suitable vacuum sealer. I have previously written about "How to Choose a Vacuum Sealer". Those with questions can refer to it for

getting more information. "How to choose a vacuum sealing machine", please check the following website address. *Nozzle type vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1116 *Non-nozzle type vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1115

*Chamber vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1114 2. Why can't I use PE bags for vacuum packaging? A: Due to the density of the bag material. Even after air is removed and sealed, air can still seep back into the bag. Therefore,

after packaging, if left alone for a period of time, the vacuum effect will be lost. 3. What type of bag material is suitable for vacuum packaging? A: The most common vacuum bag materials are nylon (NY) bags and aluminum foil bags. Both of these materials

can prevent air from seeping back into the bag and maintain a vacuum state inside the bag. 4. Why can't I maintain a vacuum effect even after using vacuum bags? A: If you have confirmed that you are using vacuum bags, you can first check if the seal

is defective. Some vacuum bags are too thick and require a longer sealing time, such as foldable bags (tea bags), which have four layers. If the seal is confirmed to be perfect, check if there are any holes in the vacuum bag. When vacuuming, the bag will adhere

closely to the contents. If the contents have sharp edges, it is possible to puncture the bag and lose the vacuum effect. 5. Many users who have bought vacuum sealers or vacuum bags are confused when they find that they can't remove the air from flat

vacuum bags. What should they do? A: This is because they have purchased a vacuum sealer without a nozzle. The non-nozzle type vacuum sealers have to use the special vacuum bags (channel bags, embossed bags and gusset bags) to remove air, so if users use flat

vacuum bags, they will find the vacuum sealer and vacuum bag can't work. 6. If someone accidentally purchases a non-nozzle vacuum sealer (such as FOODSAVER), what types of vacuum bags can they use? A: The following types of vacuum bags can be used:

(1) Vacuum sealer embossed bags (vacuum channel sealer bags): vacuum bags with straight stripes. (2) Fold-over bags: such as tea bags with two sides folded in to become a four-layer bag. (3) Back-sealed bags: vacuum bags with one side flat and the

other side with an additional spine. Remember to choose aluminum foil bags and nylon bags as the material for vacuum bags. 7. What is the difference between a vacuum flat bag and a vacuum striped channel sealer bag? A: A vacuum flat bag is like a regular

plastic bag with both sides being flat are smooth, but the material of a vacuum flat bag is made of nylon (NY) or aluminum foil. A vacuum channel sealer bag has one flat smooth side and the other side has straight stripes. 8. Why can a vacuum channel

sealer bag be used with a Non-nozzle vacuum sealer? A: The key is in the straight stripes of the vacuum channel bag. The structure of a Non-nozzle vacuum sealer requires a straight stripe to create a channel for the air inside the bag to be removed. If the

stripes are too shallow, it may still be unable to vacuum out the air.

MORE

2024/12/19

Vacuum Packaging in Agricultural Product Processing: Extending Freshness and Enhancing Qua

Vacuum Packaging in Agricultural Product Processing: Extending Freshness and Enhancing Quality In the agricultural product processing industry, one of the key challenges is preserving the freshness of ingredients, extending shelf life, and enhancing

product quality. With the advancement of vacuum packaging technology, more and more agricultural product processing factories are adopting this technique, achieving remarkable results. Vacuum packaging not only effectively extends the shelf life of agricultural

products but also protects their nutrients and original flavors. Below are the main applications of vacuum packaging in agricultural product processing: 1. Extending the Freshness of Agricultural Products For fresh vegetables, fruits, meat, and seafood,

maintaining freshness after processing is a critical concern for processing factories. Vacuum packaging effectively isolates air, reducing the exposure of ingredients to oxygen, which helps slow down oxidation and prevent spoilage. This not only extends the

freshness of agricultural products but also ensures that their taste and nutrients are preserved, meeting consumer demand for fresh products. 2. Optimal Storage for Frozen Foods Frozen agricultural products, such as frozen vegetables, fruits, and meats,

are common products in many processing factories. Using vacuum packaging can effectively prevent freezer burn, preserving the texture and nutritional value of the food. Vacuum sealing reduces moisture loss, maintains the color, taste, and texture of the product,

ensuring it remains in optimal condition even after long storage, making it suitable for distribution and sales. 3. Preservation of Dry Goods and Dried Fruits Dry fruits, dried vegetables, and other dry goods play an important role in agricultural product

processing. The preservation of these products heavily relies on vacuum packaging, which effectively prevents moisture and insect infestation, protecting the taste, aroma, and nutritional value. Whether it's nuts, dried fruits, or herbs, vacuum packaging extends

shelf life, reducing losses caused by environmental factors. 4. Meeting the Demand for Ready-to-Eat Agricultural Products As consumer demand for convenient foods rises, many agricultural product processing factories have begun producing ready-to-eat

agricultural products. These products, such as pre-packaged salad greens and frozen ready-to-eat meals, benefit from vacuum packaging, which helps retain freshness and nutrients. Vacuum packaging not only maintains the taste and texture of the products but

also enhances their market competitiveness, meeting consumers’ desires for both health and convenience. 5. Seed Packaging and Protection Agricultural product processing factories are not only concerned with food processing but also the handling of agricultural

seeds. Seed packaging requires sealing to maintain dryness, prevent moisture, and protect the seeds from environmental factors. Vacuum packaging plays a significant role in seed packaging, improving germination rates and ensuring the productivity of crops.

Conclusion Vacuum packaging technology in agricultural product processing has a wide range of applications, from preserving freshness, freezing, and dry goods storage to meeting the demand for ready-to-eat products. It plays a vital role in extending shelf

life, protecting the flavor of ingredients, and enhancing market competitiveness. As the need for diverse agricultural products and high-quality food grows, vacuum packaging continues to be an essential technology for agricultural processing.

MORE

_1.jpg)

.jpg)

_1.jpg)

_1.jpg)