Sealing length: 30cm.

Can control vacuum and seal time.

Suitable for packing products: tea leaves, soap, meat, nuts, electronic component etc.

Sealing length: 30cm.

Can control vacuum and seal time.

Suitable for packing products: tea leaves, soap, meat, nuts, electronic component etc.

Non-nozzle Vacuum Sealer:

• Made in Taiwan.

• Equipped with oil-less pump inside.

• Made in stainless steel, keeps hygiene and safety.

• Sealing operation:

(1) Manual seal: by hand operation.

(2) Pressure sensor switch control: if the air inside of bag is vacuumed out, the sealer will seal the bag automatically.

(3) Setting vacuum time.

• Equipped with counting device: after vacuuming and sealing, the machine will count the operating number of times automatically. It can be clearly to know how many bags that were finished.

• Some bag can be vacuumed at same time, depends on bags width.

• Mini machine, easy to use and move.

• Vacuum package to keep food fresh longer and keeps the precious articles from humidity.

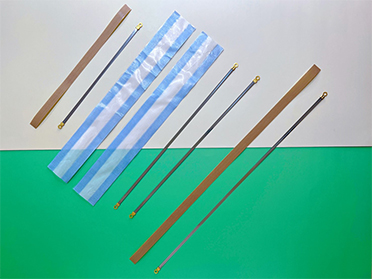

• Available for: aluminum foil gusset bag, Nylon gusset vacuum bags and vacuum embossed bag only.

• Suitable for dry and solid goods only.

• Option: 200mm commercial vacuum sealer

| Model No. | DS-VM305 |

|---|---|

| Voltage/Ampere | 110V, 220V |

| Power | 550W |

| Vacuum capacity | 26.0” hg |

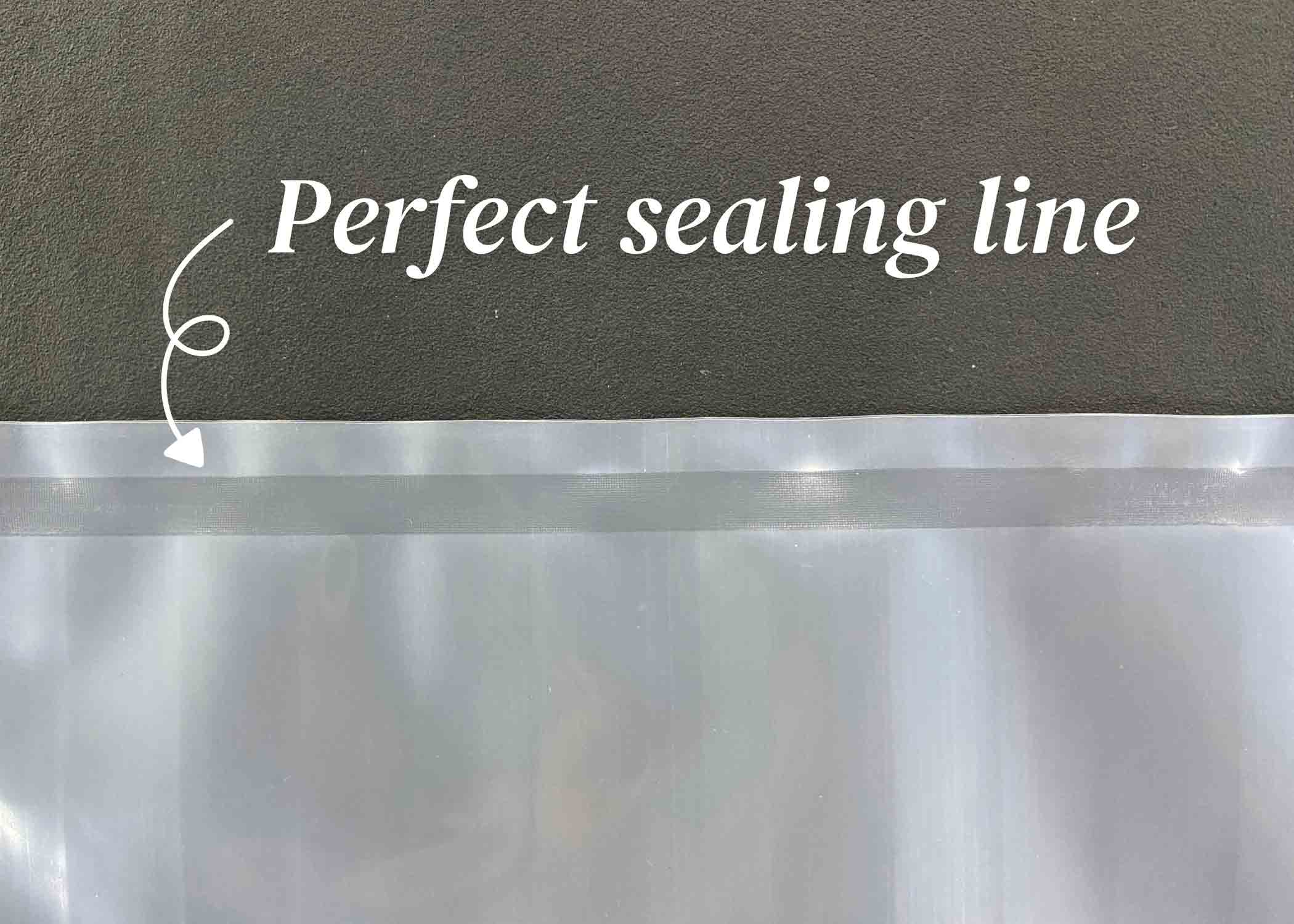

| Max.sealing | 300.0 x 5.0 mm |

| Vacuum time | 0.0–99.0 sec. (adjustable) |

| Sealing time | 0.0–6.0 sec. (adjustable) |

| Cooling time | 0.0–10.0 sec. (adjustable) |

| Machine weight | 10.00 kgs |

| Machine size | 395 x 310 x 150 mm |

Non-nozzle Vacuum Sealer:

.jpg)