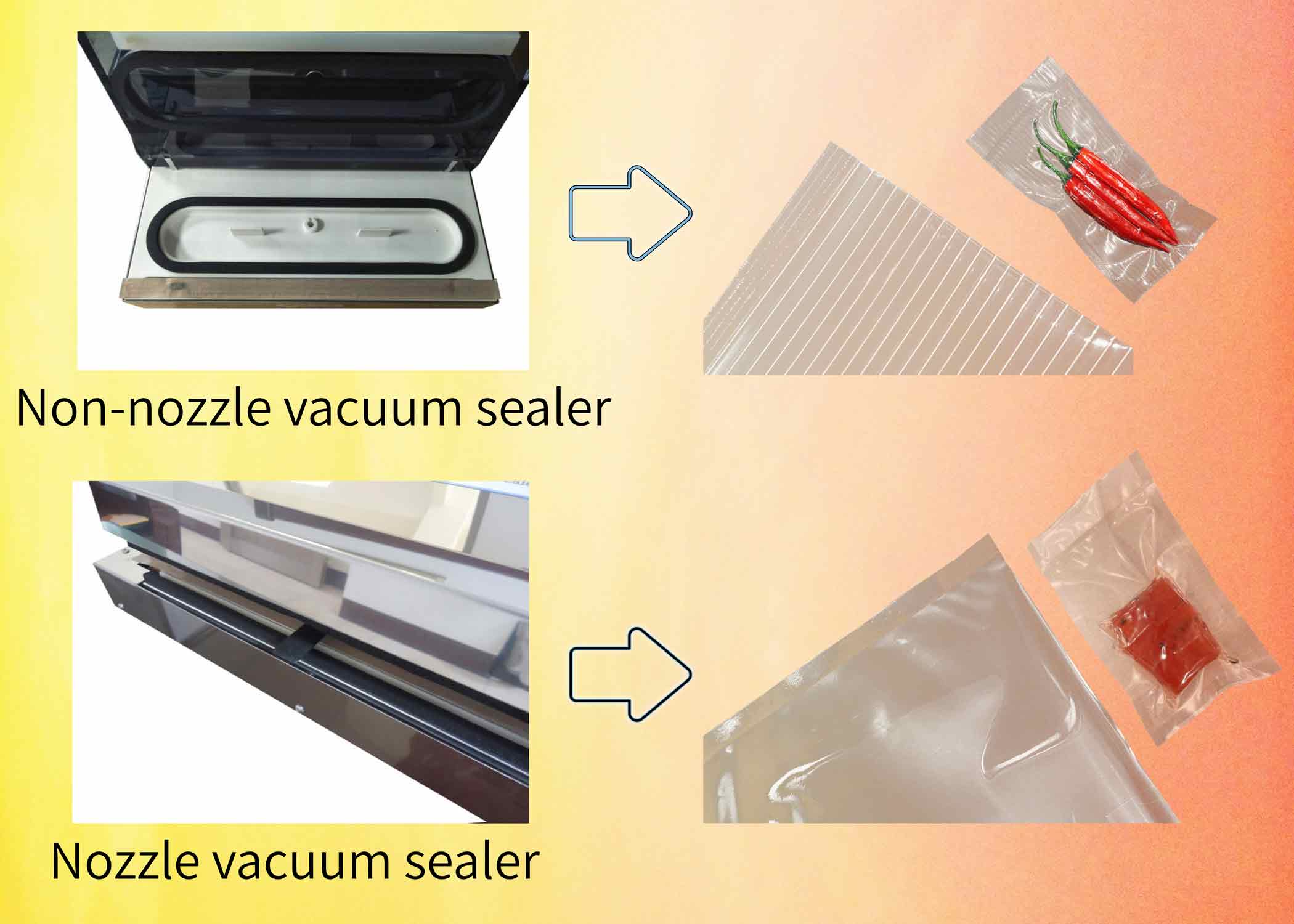

For non-nozzle vacuum sealer.

FDA and EU approved, NO BPA, available for microwave.

Could cut the length of bag which depends on user’s demands.

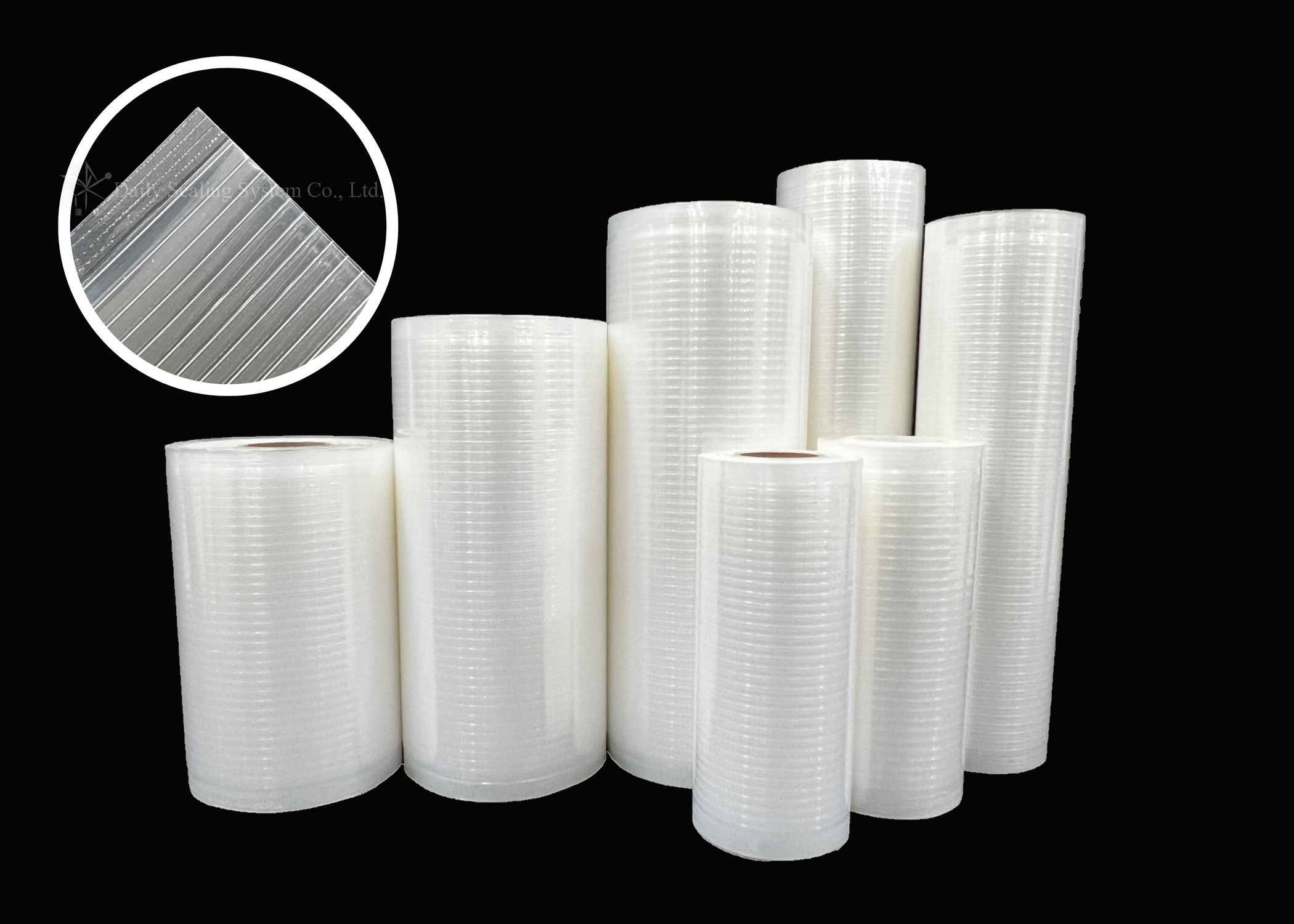

Vacuum Sealer Embossed Roll Bags:

• Made in Taiwan.

• Nylon Channeled (Embossed) Bags are special for non-nozzle vacuum sealer, embossed lines of inside bag advantages air out.

• FDA and EU approved, NO BPA, endure high temperature, available for microwave.

• Vacuum roll bag: could cut the length of bag which depends on user’s demands.

• Vacuum packing machine nozzle type vacuum sealer can also be suitable used.

• Vacuum Sealer Embossed Roll Bags Available for:

(1) Meat-processed food:Jerk meat and salted meat (preserved meat).

(2) Seafood:Fishes and other seafood…etc.

(3) Processed food:frozen food、microwave food...etc.

(4) Other food:rice, Chinese herbal medicine, tea leaves, bean products, seeds, dried food and nuts.

(5) Other:Electronic parts and hardware components.

• Options:

(1) Vacuum sealer pouch bag (Model: B02-2030)

(2) Non-nozzle vacuum sealing machine (Model: DS-VM405)

| Item No. | Size for Roll bag |

| B01-1510 | 150mm x 10M x 0.085mm (WxLxT) |

| B01-2010 | 200mm x 10M x 0.085mm (WxLxT) |

| B01-2510 | 250mm x 10M x 0.085mm (WxLxT) |

| B01-2810 | 280mm x 10M x 0.085mm (WxLxT) |

| B01-3210 | 320mm x 10M x 0.085mm (WxLxT) |

| Item No. | Size for Roll bag |

| B01-1520 | 150mm x 20M x 0.085mm (WxLxT) |

| B01-2020 | 200mm x 20M x 0.085mm (WxLxT) |

| B01-2520 | 250mm x 20M x 0.085mm (WxLxT) |

| B01-2820 | 280mm x 20M x 0.085mm (WxLxT) |

| B01-3220 | 320mm x 20M x 0.085mm (WxLxT) |

Vacuum Sealer Embossed Roll Bags:

.jpg)