Sealing length: 30cm.

Small type.

Made in Japan.

Suitable for the store using.

Sealing length: 30cm.

Small type.

Made in Japan.

Suitable for the store using.

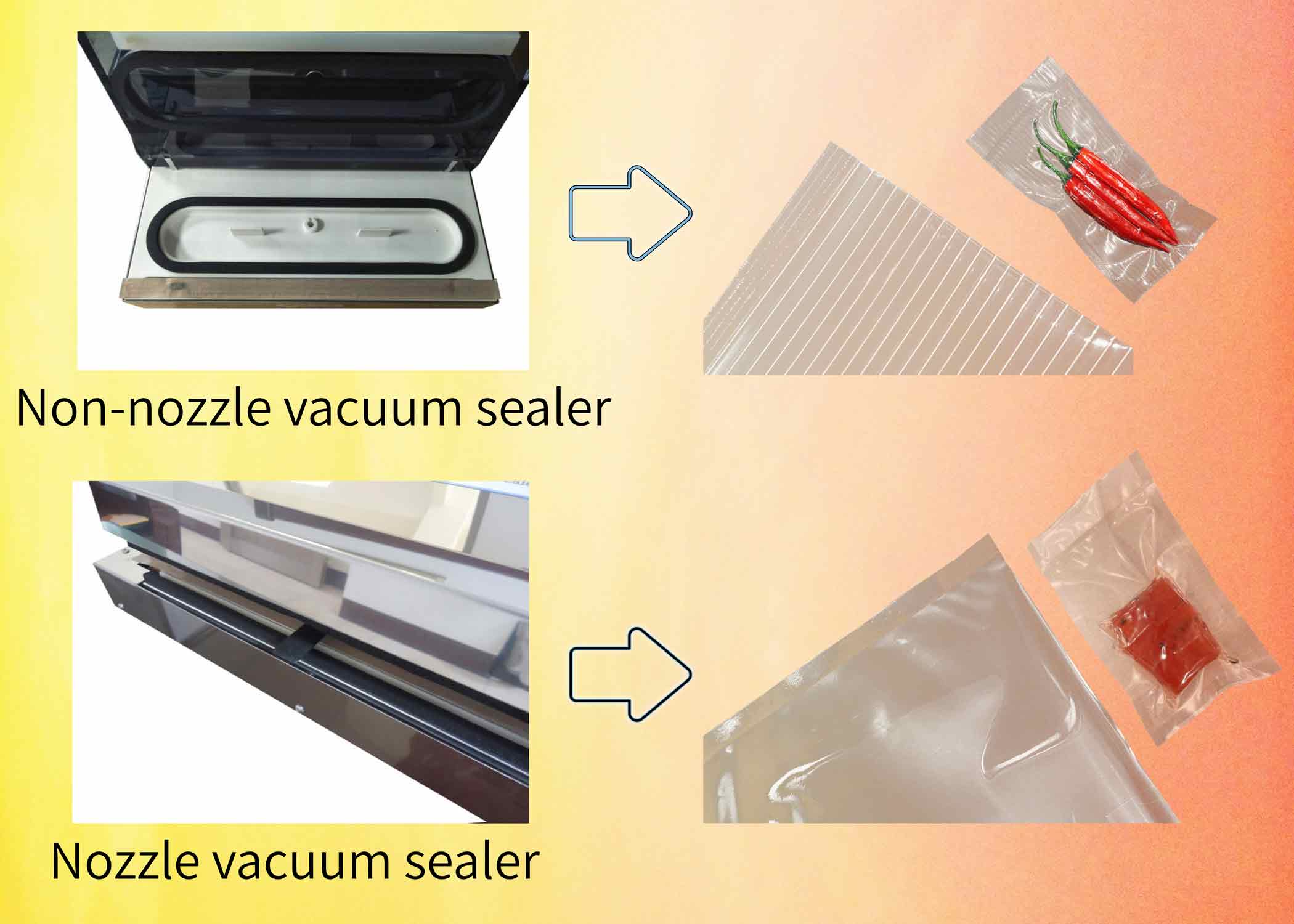

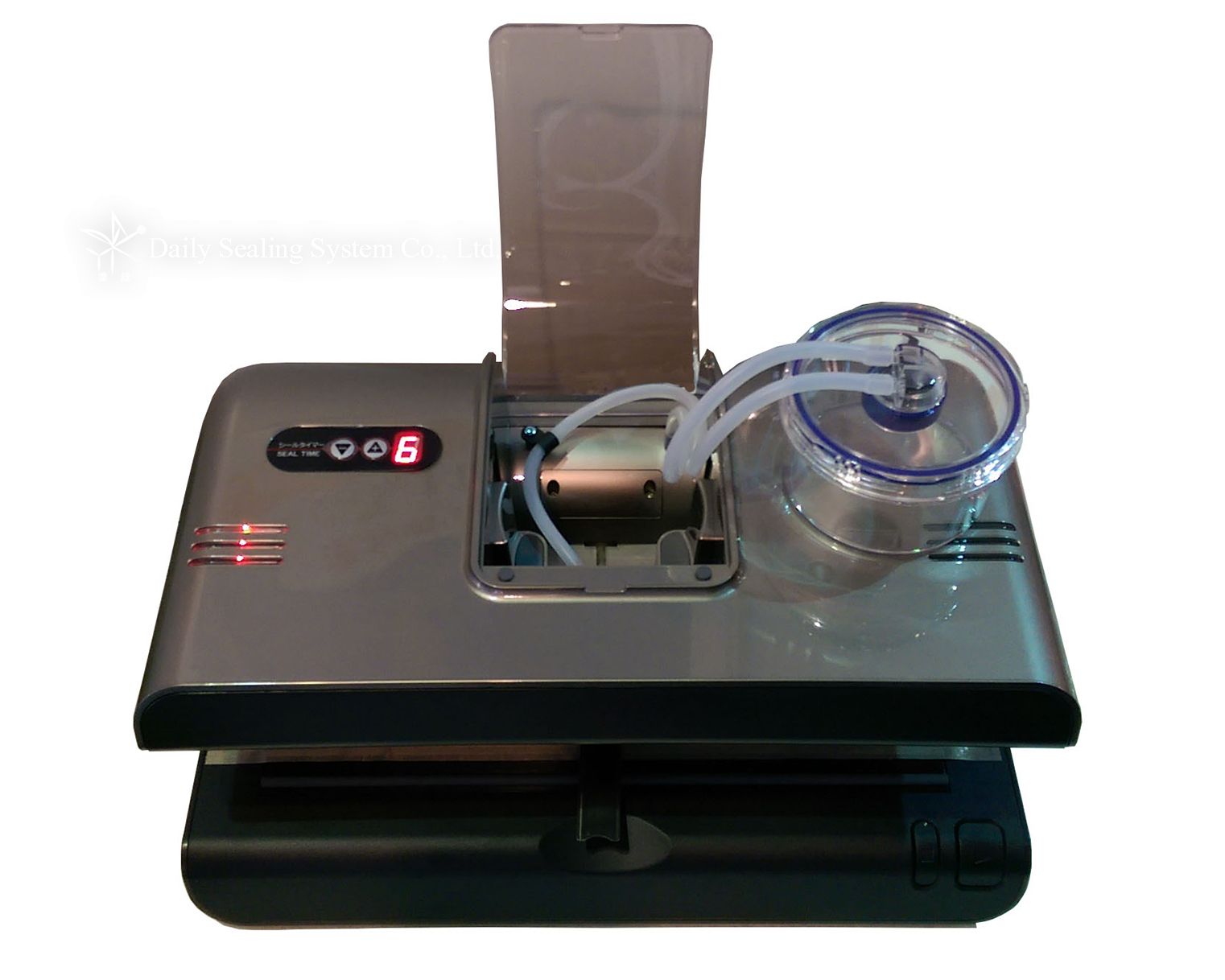

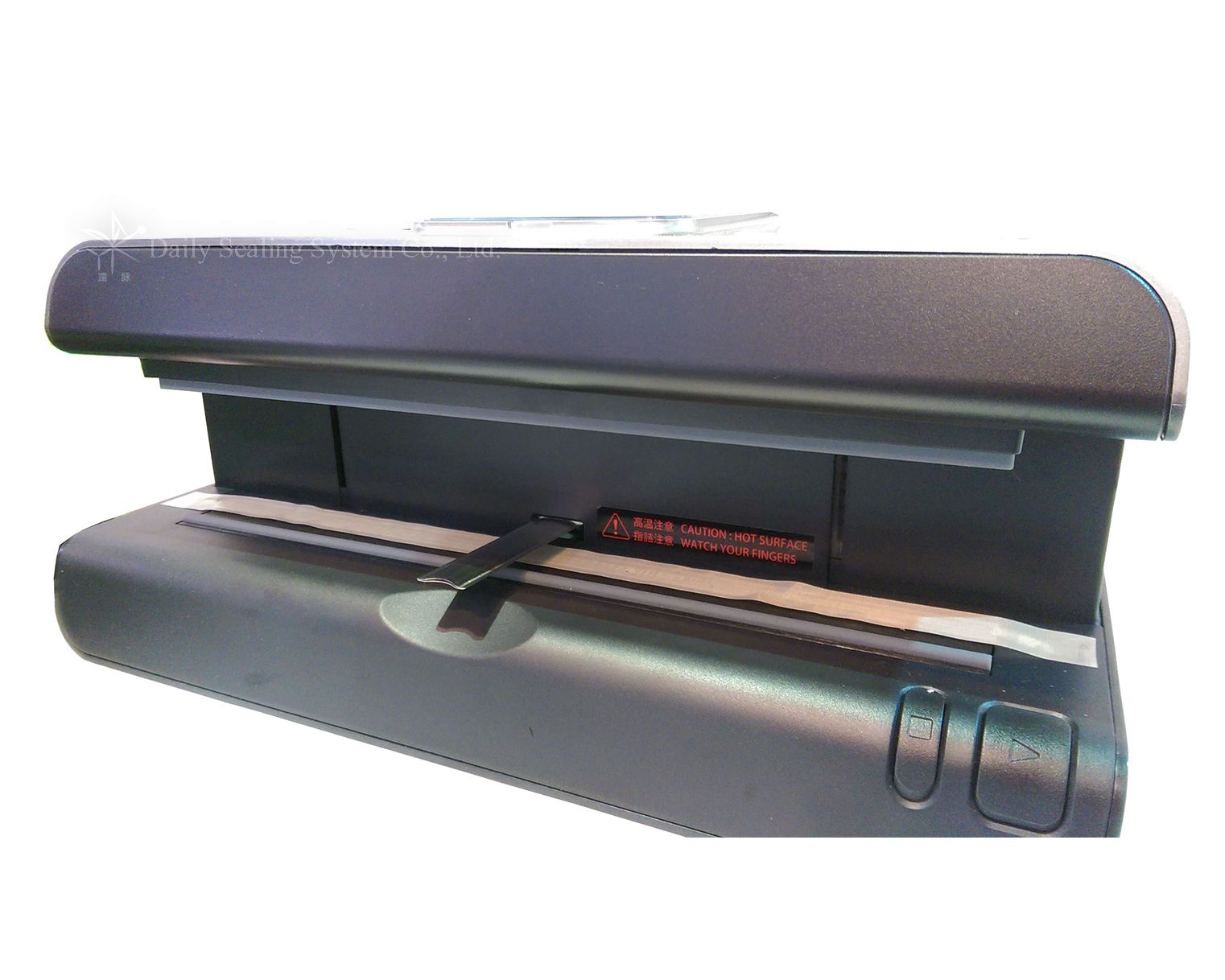

Tabletop Nozzle Type Vacuum Sealer:

• Made in Japan.

• ABS material.

• One touch for fully automatic vacuuming and sealing operations and semi-automatic modes.

• Comes with an in-built water collection cup, can vacuum and seal even highly moist contents.

• Can be cleaned easily with its detachable Nozzle.

• In-built Adapter supports all of Voltages (100V-240V).

• Maintain food’s freshness & flavor; antiseptic, and mold resistant

• Tabletop Nozzle Type Vacuum Sealer Extend storage period for packed goods.

• Prevents electronic & hardware parts from rusting & dampening.

• It’s suitable for all kinds of vacuum bags, such as NY bags, Aluminum bags.

| Model No. | DP-VS320 |

|---|---|

| Voltage/Ampere | AC 100V-240V 1 phase |

| Power | 200W |

| Vacuum capacity | -80 Kpa |

| Max.sealing | 5mm*320mm |

| Vacuum time | 1-60 sec |

| Sealing time | 1-9.0 sec. |

| Cooling time | In-built |

| Machine weight | 4.4 KG |

| Machine size | 394*266*175 (mm) |

Tabletop Nozzle Type Vacuum Sealer Video: