Designed for vacuum container and air valve bags, it can be easy to vacuum air out.

- Detail

- Video

Vacuum Machine:

• Designed for vacuum container and air valve bags, it can be easy to vacuum air out.

• Users turn on and off power switch to control vacuum time directly, easy to operate.

• The vauum lid could be custom made which depends on customer`s demands.

• We also offer vacuum containers.

Specification

| Model No. | DAV-MB |

|---|---|

| Voltage/Ampere | 110V / 2.5A, 220V |

| Power | 280W(110V) |

| Vacuum time | Adjustable |

| Machine weight | 3.32 kgs |

| Machine size | 218 x 205 x 151 mm |

Vacuum Machine:

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

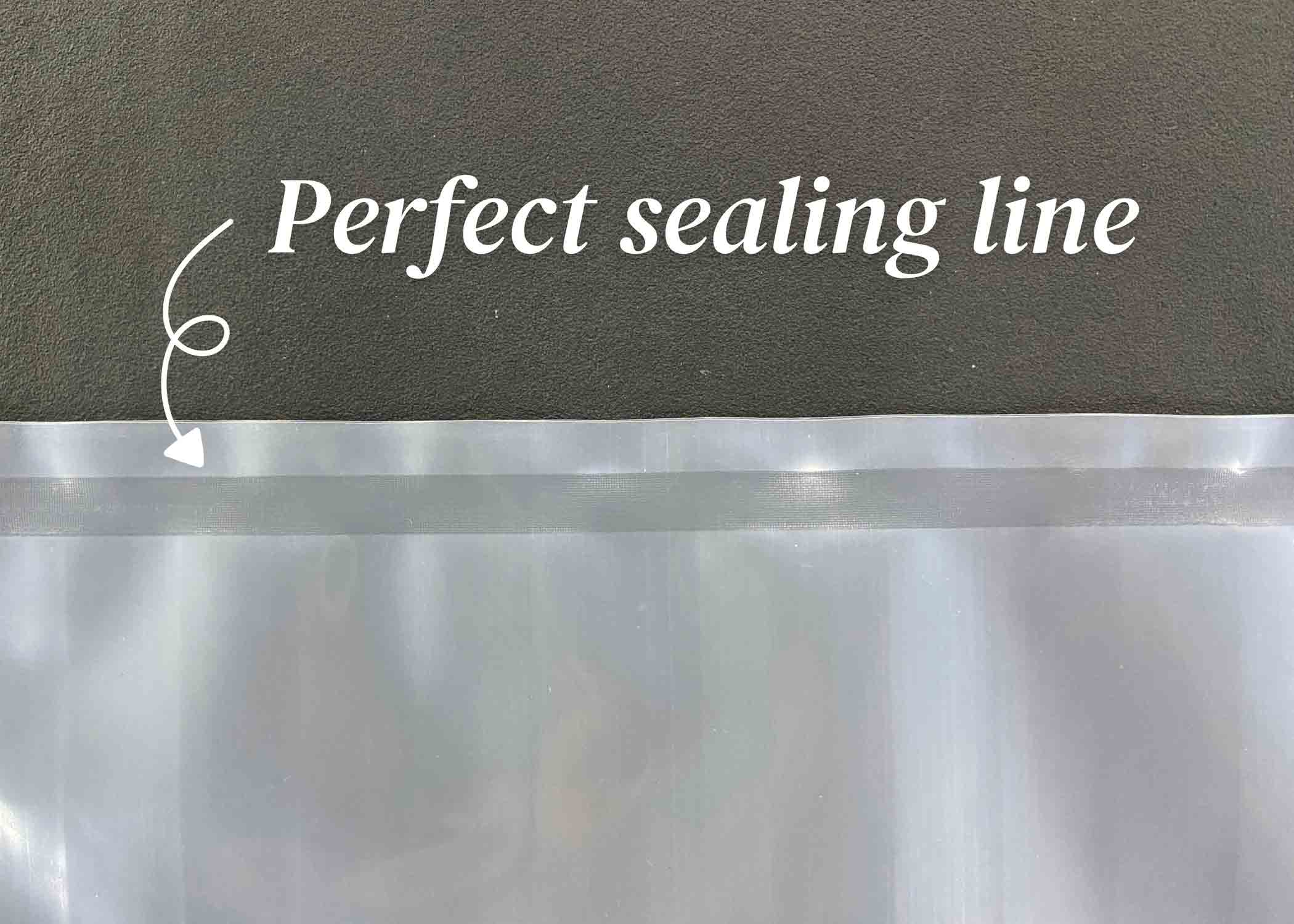

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2023/9/5

What are the applications of vacuum bag packaging?

Vacuum bags have a wide range of applications, especially when used in conjunction with a vacuum sealer machine. Here are some common applications of vacuum bags: Food Storage and Preservation: One of the most common uses of vacuum bags is for storing

and preserving food items. Vacuum sealing removes air from the bag, slowing down the oxidation process and inhibiting the growth of bacteria and molds. This helps keep food fresh for longer periods, whether it's raw meats, vegetables, fruits, or pre-cooked

meals. Vacuum-sealed bags are also popular for storing leftovers and meal prep. Sous Vide Cooking: Vacuum bags are essential for sous vide cooking, a cooking method where food is placed in a vacuum-sealed bag and cooked in a precisely controlled water bath

at a consistent temperature. The vacuum-sealed bags ensure that the food is evenly cooked and retains its natural flavors and juices. Marinating: Vacuum bags can be used for marinating meats and other food items. By removing the air from the bag, the marinade

is more effectively absorbed into the food, resulting in enhanced flavors. Long-term Freezing: Vacuum-sealed bags are excellent for freezing food items. The absence of air prevents freezer burn, maintaining the quality and taste of the food even after prolonged

storage. Travel and Outdoor Activities: Vacuum bags can be used to pack clothes and other travel essentials, compressing them to save space in luggage. They are also used for storing items during camping or hiking trips to protect them from moisture and

keep them organized. Document and Jewelry Storage: Vacuum bags are useful for protecting important documents, photographs, and valuable items like jewelry from dust, moisture, and other elements that could cause damage. Organizing Household Items: Vacuum

bags can be used to store seasonal clothing, blankets, and pillows, reducing their volume for easy storage when not in use. Emergency Preparedness: Vacuum bags can be used for creating emergency kits, preserving food supplies, and organizing essential items

for disaster preparedness. Industrial and Commercial Packaging: Vacuum bags are used in various industries for packaging sensitive or perishable products, ensuring they stay fresh and intact during shipping and storage. It's essential to use vacuum bags

specifically designed for vacuum sealers to ensure proper functioning and safety. The versatility and benefits of vacuum bags make them a practical choice for various storage and preservation needs in both household and commercial settings.

MORE

2025/12/24

Pro Tips: How to Vacuum Seal Liquids and Moist Foods Without a Mess (Vacuum Sealing, Seale

Pro Tips: How to Vacuum Seal Liquids and Moist Foods Without a Mess (Vacuum Sealing, Sealer Tips) One of the biggest frustrations for new users is trying to vacuum seal liquids and moist foods. When the air is pulled out, the liquid can be drawn right

up into the machine, which can ruin the seal, damage the internal pump, and make a huge mess. Follow these pro tips to seal liquids, soups, sauces, and high-moisture items like marinated meats successfully: The

Freezer Trick (The Gold Standard): For any liquid (soups, sauces, stocks) or high-moisture food (marinated chicken), pre-freeze it for 1 to 2 hours until it is slushy or mostly solid. Once partially frozen, the liquid is too dense to be sucked up during the

vacuum process, ensuring a clean, perfect seal. The "Moist" Setting: Many modern vacuum sealers have a "moist" or "liquid" setting. This function typically pulls a weaker or slower vacuum and then seals sooner, giving the liquid less time to migrate to the

sealing bar. Leave Plenty of Headroom: Always leave more space than usual between the food and the top of the bag—at least 3 to 4 inches. This acts as a buffer zone. Use a Paper Towel Buffer: For wet-marinated meats, you can loosely place a small, folded

piece of paper towel just inside the top of the bag, right before the sealing area. It acts as a moisture trap to catch any escaping liquid before it hits the sealing strip. Double Seal: For extra protection on liquids destined for the freezer, press the

seal button a second time right after the first seal is complete. This creates a redundant double seal just above the first one, adding security against leaks.

MORE

2025/12/24

Heat Sealing Masterclass: Essential Tips for the Perfect, Airtight Seal Every Time (Heat S

Heat Sealing Masterclass: Essential Tips for the Perfect, Airtight Seal Every Time (Heat Sealing Machine, Tips) Whether you use a simple impulse sealer, a band sealer, or a vacuum sealing machine, the quality of your seal depends on mastering the process.

A perfect heat seal requires balancing three key elements: Heat, Time, and Pressure. The Three Pillars of a Perfect Heat Seal Heat (Temperature): The element must be hot enough to melt the thermoplastic material of the bag. Tip: If the plastic burns or

melts through, the heat is too high. If the bag pulls apart easily, the heat is too low. Start with a medium setting and adjust based on the material thickness (thicker materials need more heat). Time (Cooling Time): This is how long the heat and pressure

are applied to the bag. Tip: A proper heat sealing machine allows the plastic to melt, fuse together, and then cool while still under pressure. If you remove the bag too quickly, the seal will be weak. Follow the manufacturer's recommended cycle time or

wait for the cooling light/beep. Pressure: Uniform pressure ensures that the two layers of plastic are pressed together evenly. Tip: Ensure the sealing bar and the opposing pressure bar are clean. Uneven pressure (often due to debris) can lead to a wrinkled

or weak point in your seal. Maintenance for Perfect Seals To keep your heat sealing machine performing at its best, pay attention to the consumables: Heat-resistant tape/ cloth : The heat-resistant tape prevents the molten plastic from sticking to the

heating element. If the tape is worn, torn, or damaged, replace it immediately to avoid a messy, incomplete seal. Keep it Clean: Always wipe down the sealing element after use. Even minor food dust or crumbs can disrupt the bond between the plastic films.

MORE

(56).jpg)

(57).jpg)