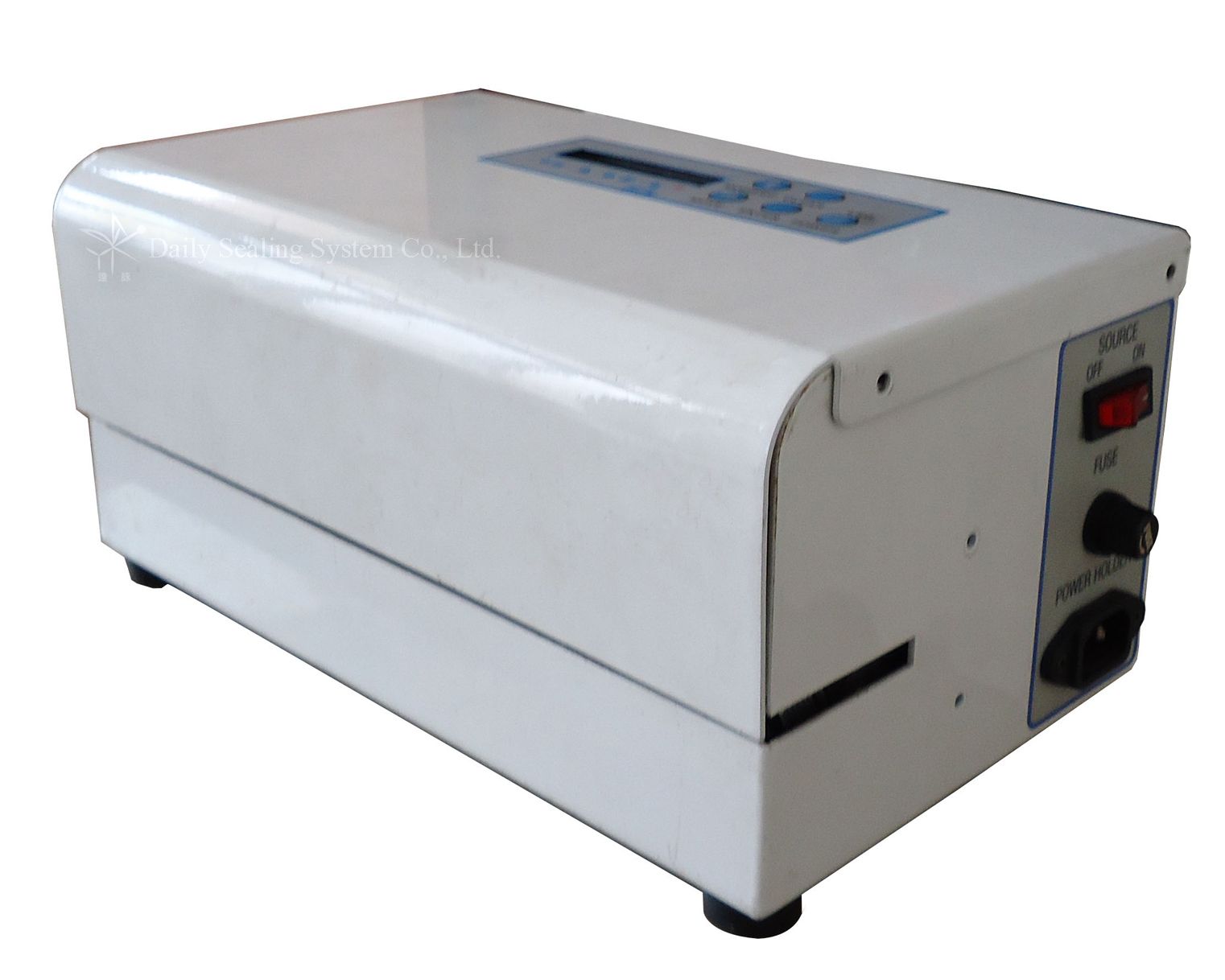

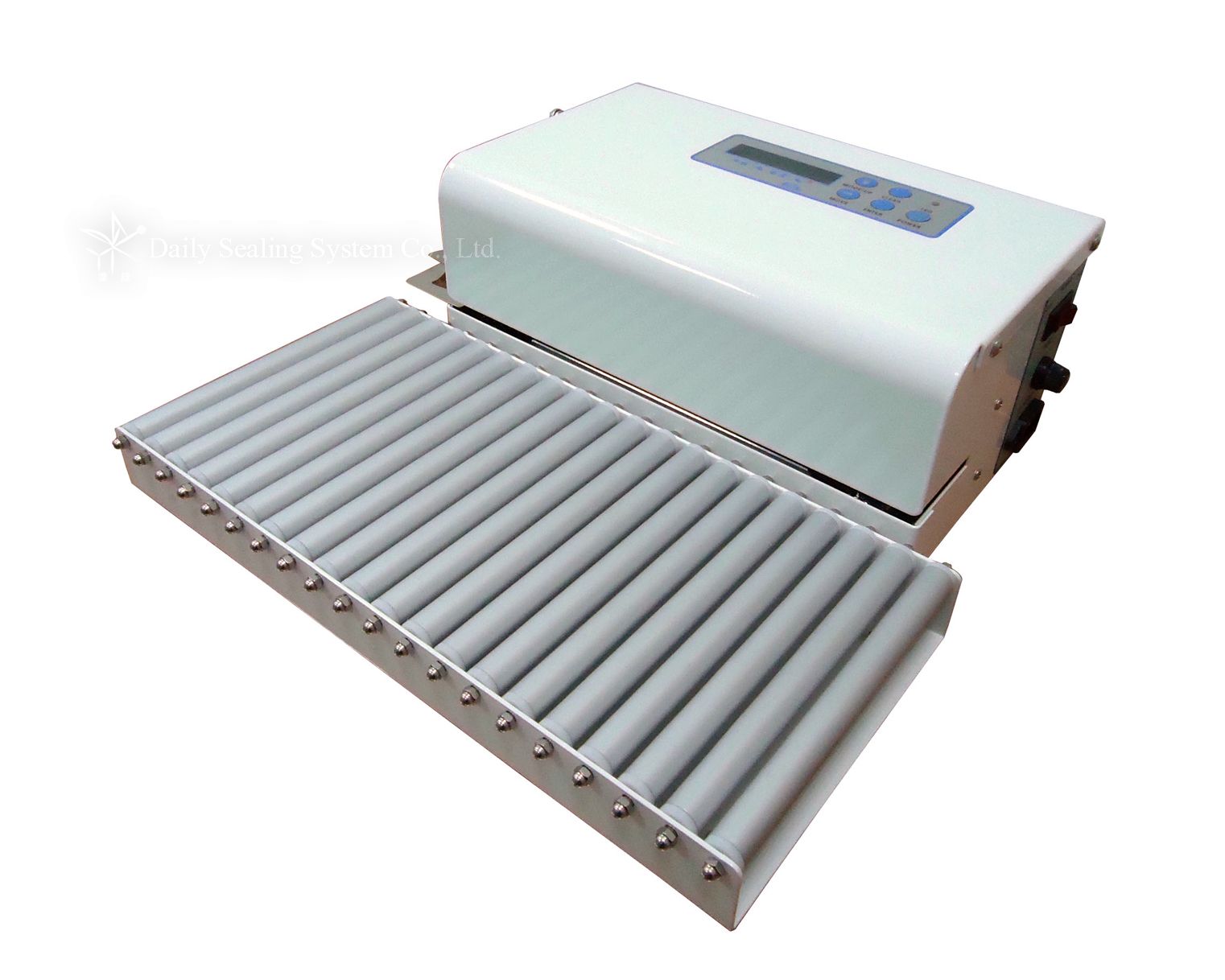

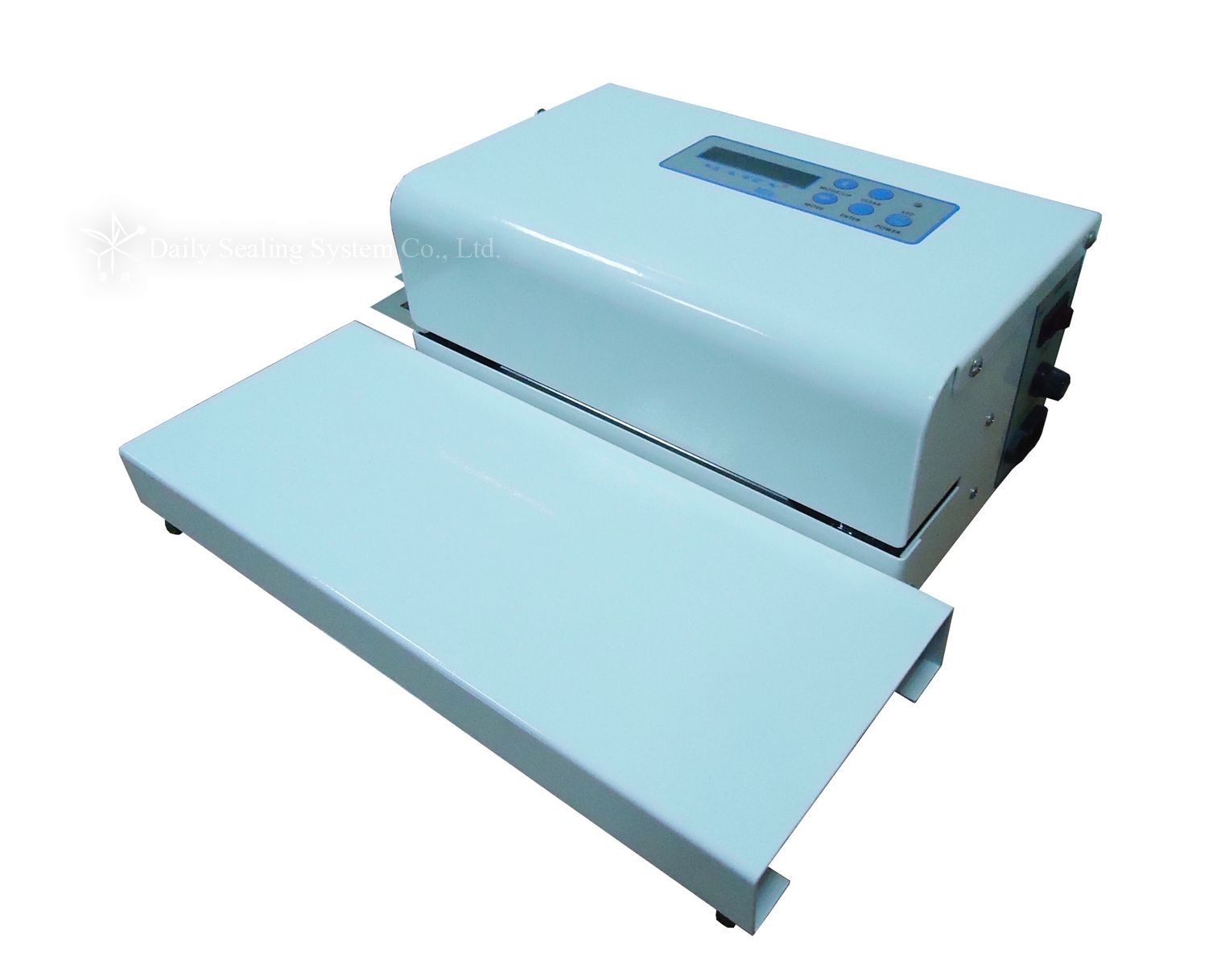

Small type band sealer for medical bags.

- Detail

- Video

Rotary sealer for sterilization bag:

• Machine material: steel plate with powder coating.

• Sealing pouch bag continually.

• Energy-saving: the motor will shut off when not in use for 5 min, but the temperature still keeps.

• Electronic thermostatic control, keeps constant and stable sealing temperature.

• Equipped the counting device, which can count the finished seals automatically and pre-set the desirous sealing

times for the same.

• The machine is mini size, which can save space and move easily.

• Available for: medical bag, sterilization bag, aluminum foil bag, tinfoil bag.

• The sound pressure levels under 70dB (A).

• CE approval.

Specification

| Model No. | DTC-200 |

|---|---|

| Sealing type | Constant Heat |

| Voltage/Ampere | 110V /3.2A, 220V /1.64A |

| Power | 360W(110V),370W(220V) |

| Machine weight | 8.10 kgs |

| Machine size | 360 x 177 x 147 mm |

| Sealing width | 12mm |

| Sealing and conveyor speed | 4.8M/ min |

| Sealing Temperate | 100 - 250℃ |

| Warm up time | 5- 10 mins |

Rotary sealer for sterilization bag:

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

2024/12/24

Vacuum Sealer Cleaning and Maintenance: A One-Stop Guide

Vacuum Sealer Cleaning and Maintenance: A One-Stop Guide Vacuum sealers are indispensable equipment in the food packaging industry, helping to maintain the freshness of food or other products and extending the shelf life of products. To ensure that vacuum

sealers operate over the long term and maintain optimal performance, regular cleaning and maintenance of the vacuum sealer is essential. Below is a series of professional steps for cleaning and maintaining vacuum sealers to help you achieve this goal. Vacuum

Sealer Cleaning Steps: 1. Daily Cleaning: After using the vacuum sealer, immediately wipe the exterior of the vacuum sealer as well as the sealing chamber and seal groove with warm water and a neutral detergent. Avoid using strong acids, strong alkalis,

or abrasive detergents that could damage the surface. 2. Inspection and Replacement of the Vacuum Sealer's Heating element: Regularly check the vacuum sealer's Heating element for damage or wear and replace it in a timely manner to maintain excellent sealing

results. 3. Lubrication of Vacuum Sealer Mechanism Parts: According to the operation manual, regularly check and apply a special lubricant to the mechanical parts of the vacuum sealer, such as conveyor belts and bearings. 4. Vacuum Pump Maintenance: For

vacuum sealer models equipped with a vacuum pump, it's necessary to regularly clean the vacuum pump filter and replace the filter element to ensure the normal operation of the vacuum pump. 5. Electrical System Inspection: Regularly check the electrical system,

including wires, plugs, and switches, to ensure they are safe and reliable. Vacuum Sealer Maintenance Suggestions: 1. Ensure Good Ventilation: When using the vacuum sealer, ensure the surrounding area is well-ventilated to prevent dust and other foreign

objects from entering the inside of the machine. 2. Inspection and Replacement of Vacuum Oil: For oil-type chamber vacuum sealers, regularly check the amount and clarity of the vacuum oil and add or replace the vacuum oil as necessary to maintain a good

vacuum. 3. Cleaning of the Sealing Area: After using the vacuum sealer, clean the sealing area to keep it free of dirt and grime, ensuring the sealing effect. 4. Selection of Appropriate Packaging Materials: Choose suitable packaging materials, especially

when vacuum sealing liquids, to prevent the liquid from being sucked into the pump. 5. Timely Replacement of Vacuum Sealer Consumables: If any worn or damaged parts are discovered, they should be replaced promptly to avoid affecting the performance of the

vacuum sealer. By following the above methods for cleaning and maintaining your vacuum sealer, you can not only ensure stable performance and efficient sealing results but also extend the lifespan of your vacuum sealer to the greatest extent. Regular maintenance

not only helps improve work efficiency but also ensures the safety of the vacuum sealing process and the hygiene quality of the food. Vacuum Sealer Cleaning and Maintenance

MORE

.jpg)

2022/12/15

Vacuum Sealer

Vacuum Pack can keep fresh and preserve longer, moisture-proof and volume reduction. Daily has many kinds of vacuum sealer could be chosen. The following is the introduction of Daily vacuum sealer for your reference. ※ Vacuum sealer type: - Non-nozzle

vacuum sealer : suitable for vacuum channeled bags, nylon gusset bags and alum. gusset bags. The length of vacuum bags is not limit. - Nozzle Vacuum Sealer : suitable for vacuum bags. The length of vacuum bags is not limit. There are two type of Daily nozzle

vacuum sealer: motor control and air control. - Chamber type vacuum sealer : suitable for all kind vacuum bags. The vacuum degree of vacuum sealers is the highest. The size of vacuum bags is limited of the vacuum chamber. This vacuum sealer is suitable for

vacuuming liquid and powder. - Vacuum band sealer : there are two type vacuum band sealer could be chosen because of vacuum degree. ※ Two type Vacuum pump: - Oil-less vacuum pump : Suitable for Vacuuming dry and solid articles, such as tea leaves, rice,

beans and electronic component etc. - Oil vacuum pump : suitable for liquid and powder articles. The vacuum degree is higher than oil-less vacuum pump. It needs to change and add the vacuum oil inside the vacuum pump when the vacuum oil is dirty. ※ Vacuum

sealer application: - For food : Keep food fresh. - For other articles : Moisture-proof, anti-mildew, dust-proof, anti-rust. For example: electronic parts. - Volume reduction : fluffy articles such as bed quilt can be reduced the volume and then easy to ship

or storage. ※ Vacuum sealer accessories : - Channel Vacuum Bag : Suitable for non-nozzle vacuum sealer. There are the straight lines on Daily channel vacuum bag. - Vacuum sealer bag : Suitable for nozzle type vacuum sealer and chamber type vacuum sealer.

- Vacuum canister : Daily vacuum canister can be vacuumed by manual or used by non-nozzle vacuum sealer. - Acrylic mold : When vacuuming, it can help the article to make the square shape, such as tea and rice. -Parts-Heating Element, Teflon tape. More details: Click

here

MORE

2024/6/13

How to choose a vacuum sealing machine? (Nozzle vacuum sealer)

In recent years, vacuum packaging has become very popular, vacuum packaging keeps damp proof, extended shelf life, and reduced storage space. There are various types of vacuum sealing machines available on the market. How to find a suitable vacuum sealer

for your product. The following are specially divided into three categories for the vacuum sealers sold on the market (Chamber Vacuum Sealer, Non-nozzle Vacuum Sealer, and Nozzle Vacuum Sealer) introduce advantages and disadvantages. There are other places

to pay attention to when buying, hope to help everyone buy a suitable vacuum sealer, and enhance the quality of our product. ※ Nozzle vacuum sealer At present, the nozzle vacuum sealer is widely used in the electronics industry. The Nozzle vacuum

sealer and Non-nozzle vacuum sealer are also external, The difference is that the nozzle vacuum sealer uses the nozzle to extend into the vacuum bag to extract the air. Available for vacuum flat bags and aluminum flat bags. Non-nozzle vacuum sealer without

a nozzle. Therefore, only the strips of the vacuum stripe bag can be used to create a pipeline to allow the air to be drawn out. The reason why the nozzle vacuum sealer has a nozzle, after the vacuum, the nozzle must be retracted into the machine and can be

sealed, so when the nozzle moves, a little air enters. Therefore, the vacuum degree of the nozzle vacuum sealer is lower than that of the other two vacuum sealers. The nozzle vacuum sealer is divided into the pneumatic type and electromagnet due to

the driving mode. The advantage of the pneumatic nozzle vacuum sealer is the low sound, the disadvantage is that you need to connect the air compressor. The electromagnetic nozzle vacuum sealer doesn't need to be connected to an air compressor, but the sound

is loud during operation. Most Nozzle vacuum sealers are designed for products with little moisture or powder, add a water filter, keep water and powder in the water filter, Don't allow moisture and powder to flow into the machine, and Avoid damage

to parts. If the product itself is water or powder, never choose a Nozzle vacuum sealer, because when pumping, the nozzle extends into the vacuum bag, it will directly remove the water and powder, It's recommended to choose the Chamber vacuum sealer, when

the Nozzle vacuum sealer in operating, the way the nozzle is placed and the position of the product are very important, related to the vacuum effect. When the vacuum is recommended, keep the nozzle as close as possible to the product, and avoid sticking vacuum

flat bags when pumping, this causes the nozzle to be unable to pump air, but be careful that the nozzle is not blocked the product, it can't be pumping. When operating the Nozzle vacuum sealers, please pay special attention to this technique. Same

to a Non-nozzle vacuum sealer, there are plastic casings for sale in the market. Nozzle vacuum sealer with metal shell (steel plate with powder coating and stainless steel), small size vacuum sealer with plastic casing, cheap price, but long-term operating

with high frequency, it's not recommended to buy the Nozzle vacuum sealer with a plastic casing, because the vacuum sealer will generate heat when sealing, use for a long time, the sealing seat with continuing to heat when the temperature is too high, the

plastic case may be deformed. Just for household or small amounts of use, a Nozzle vacuum sealer can be purchased in a plastic case. If it's a factory or a long-term operator, it's recommended to purchase a Nozzle vacuum sealer with a stainless steel housing,

in addition to not worrying about the deformation of the sealing seat due to high temperature, the vacuum pump installed inside is larger than the Nozzle vacuum sealer with plastic casing, continuous use is not afraid of failure, and the vacuuming ability

is also strong. The Nozzle vacuum sealer is available for a vacuum flat bag, cheaper than a vacuum stripe bag. However, due to the control of the nozzle entering and leaving, the structure is more complicated than the Non-nozzle vacuum sealer. Therefore,

the price of the Nozzle vacuum sealer is higher than that of the Non-nozzle vacuum sealer, price comparison with the Chamber vacuum sealer depends on the vacuum pump built into the Chamber vacuum sealer, Nozzle vacuum sealers are more expensive than Oil-less

type Chamber vacuum sealer, but is lower than the oil type Chamber vacuum sealer. Generally, there is only one nozzle of the Nozzle vacuum sealer, it can add nozzles and inflatable functions according to customer needs, most of them are filled with

nitrogen, option to pump first and then inflate, or function settings such as inflate and then pump after pumping. In addition, there are also inflatable sealing machines that only inflate, it also uses a nozzle to fill the gas into the vacuum bag. The inflatable

has moisture-proof, the advantages of retaining freshness and anti-collision, mostly used in the food industry. The Band sealer also develops the air extraction function, it also uses the nozzle to suck out the air, which belongs to a Nozzle vacuum

sealer, generally known as a Continuous vacuum sealer. The price is much higher than other types of vacuum sealers, and the structure of the Band sealer will also affect the vacuum degree, so the price is also different, to choose a Continuous vacuum sealer,

except for the price, the vacuum degree is also a factor to consider. When purchasing a vacuum sealer, factors to consider include price, the types of vacuum bags it can use, vacuum efficiency, the size and type of products to be sealed, and the operating

method. No matter what kind of product you want to vacuum, it's recommended to bring the product to the site for testing before purchasing, test the vacuum effect and understand how to operate it, this will allow you to choose the most suitable vacuum sealer

for your needs.

MORE

.jpg)