•Sealing length: 75cm.

•Suitable for PP, PE, PVC, NY etc. material bags.

•Timer control

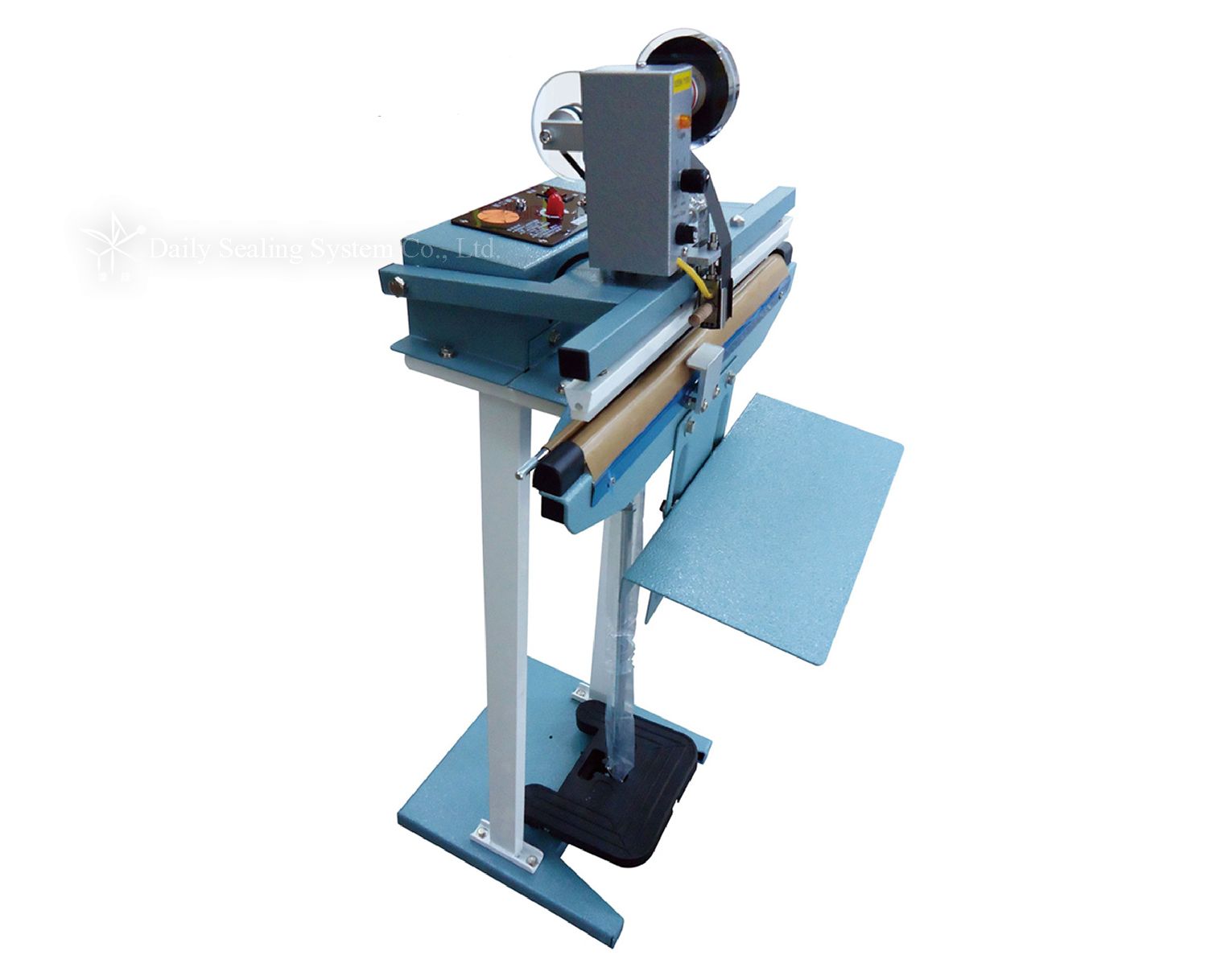

Foot type impulse sealer:

• No preheating required.

• Available with PE, PP, PVC, OPP, POF…plastic bag.

• Sealing width could be 2.7mm, 5mm or 10mm

• Additional accessories:

(1) Can add an electric magnet or pneumatic eqipment for pedal switch controled. labor-saving.

(2) Date coder.

• For other lengths sealing machine, please contact us.

|

Item No. |

|||

|

Voltage |

100V, 110V, 120V, 220V, 240V |

||

|

Max. sealing |

300x2.7mm or |

450x2.7mm or |

600x2.7mm or |

|

Machine weight |

16 kgs |

18kgs |

21kgs |

|

Machine size |

380x340x880mm |

530x340x880mm |

680x340x880mm |

|

Item No. |

||

|

Voltage |

100V, 110V, 120V, 220V, 240V |

|

|

Max. sealing |

750x2.7mm or |

900x2.7mm or |

|

Machine weight |

22kgs |

25kgs |

|

Machine size |

830x340x880mm |

980x340x880mm |

| Model No. | DS-750F |

|---|---|

| Sealing type | Impulse Heat |

| Voltage/Ampere | 100V,110V,120V,220V,240V |

| Max.sealing | Max:750.0 x 2.7 mm or 750.0 x 5.0 mm |

| Machine weight | 22.00 kgs |

| Machine size | 830 x 340 x 880 mm |

75cm Foot type impulse sealer:

.png)