For nozzle type vacuum sealer and chamber type vacuum sealer.

- Detail

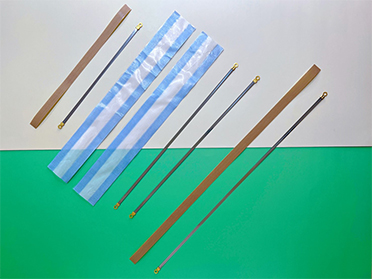

Vacuum Sealer Roll Bags:

• Material: Nylon + PE.

• It is suitable used for Nozzle vacuum sealer and Chamber vacuum sealer.

• Keep food fresh and prevent the humidity for electronic parts or hardware components.

• Available for:

(1) Meat-processed food:Jerk meat and salted meat (preserved meat).

(2) Seafood:Fishes and other seafood…etc.

(3) Processed food:frozen food、microwave food...etc.

(4) Other food:rice, Chinese herbal medicine, tea leaves, bean products, seeds, dried food and nuts.

(5) Other:Electronic parts and hardware components.

• It could customize, depends on user’s need.

| Item No. | Size for Roll bag |

| B15-1510 | 150mm x 10M x 0.080mm (W x L x T) |

| B15-2010 | 200mm x 10M x 0.080mm (W x L x T) |

| B15-2510 | 250mm x 10M x 0.080mm (W x L x T) |

| B15-3010 | 300mm x 10M x 0.080mm (W x L x T) |

| B15-3210 | 320mm x 10M x 0.080mm (W x L x T) |

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

.png)

2025/2/18

Vacuum Packaging in the Foodservice Industry: Enhancing Efficiency, Freshness, and Quality

Vacuum Packaging in the Foodservice Industry: Enhancing Efficiency, Freshness, and Quality In modern foodservice, vacuum packaging has become an essential tool for many restaurants and food businesses. This technology not only helps extend the shelf life

of ingredients but also improves food quality, reduces waste, and enhances operational efficiency. Here are the main applications of vacuum packaging in the foodservice industry: 1. Extending the Freshness of Ingredients For restaurants, managing the freshness

of ingredients is crucial. Vacuum packaging effectively isolates food from air, reducing oxidation and bacterial growth, which helps extend the shelf life of ingredients. Whether it's meat, vegetables, or seafood, vacuum packaging helps preserve freshness

and reduce spoilage, ensuring less food waste. 2. Prepping Ingredients for Increased Efficiency During busy times, restaurants often need to prep ingredients in advance. Vacuum packaging allows kitchens to prepare ingredients ahead of time while maintaining

their freshness. For example, vacuum-sealing chopped vegetables, marinaded meats, or pre-mixed seasonings ensures quick access to fresh ingredients when needed. This increases efficiency and speeds up food preparation. 3. Improving Consistency and Quality

of Dishes Vacuum packaging ensures consistency and quality, which is especially important in high-end or chain restaurants where customers expect a high standard. By vacuum-sealing ingredients before cooking, restaurants can better control the quality of food,

maintaining consistent taste, texture, and presentation. This results in a more reliable dining experience for customers. 4. Long-Term Storage of Frozen Foods For ingredients or prepared dishes that need to be stored for a long period, vacuum packaging is

ideal. Restaurants can vacuum-seal and freeze pre-made dishes (like roasted meats or stews) to retain their flavor and quality. Vacuum packaging minimizes freezer burn and moisture loss, ensuring that food stays in top condition even after extended storage.

When needed, the vacuum-sealed food can be defrosted and reheated for quick service. 5. Reducing Kitchen Waste Vacuum packaging helps reduce food waste in restaurant kitchens. By extending the shelf life of ingredients, restaurants can buy in bulk and store

leftovers properly without worrying about spoilage. This reduces food waste and cuts costs, helping businesses operate more efficiently. 6. Food Delivery and Takeout With the rise of food delivery services, many restaurants need to ensure that food maintains

its quality during transportation. Vacuum packaging plays a significant role in the takeout business by preserving the freshness of food while preventing texture and flavor changes during delivery. This ensures a better customer experience and helps sustain

the quality of food in takeout or delivery orders. 7. Meeting Special Dietary Needs Vacuum packaging can help restaurants cater to customers with special dietary needs (such as allergies or vegetarian diets). Restaurants can prepare meals in advance according

to specific dietary requirements and vacuum-seal them for storage. This ensures that the food remains fresh and safe while meeting customer preferences or restrictions. Conclusion Vacuum packaging technology offers multiple benefits to the foodservice industry,

from improving ingredient management and reducing waste to enhancing food quality and customer satisfaction. As the demand for high-quality food and efficient service continues to grow, vacuum packaging will undoubtedly become an indispensable tool in the

future of foodservice operations.

MORE

2024/7/12

Q&A-Why can’t the vacuum effect be maintained after using the vacuum sealer?

Why can’t the vacuum effect be maintained after using the vacuum sealer? The following are possible reasons. Users can check by themselves first. 1. The wrong material of packing bags: the material of plastic bags is PE, PP which can’t maintain the vacuum

effect. The air will enter into the bags after the vacuum sealer finishing working. It is recommended to choose Nylon bags, Aluminum foil bags which can maintain the vacuum effect for a long time. 2. The sealing line is not sealed well: please check whether

the sealing line is complete or not. If the sealing line is not closed, the air will run into the bags. (1) If the bag is too thick, and the vacuum sealer wasn't set for enough sealing time, the heat wasn't enough to seal the bag. If the vacuum sealer can

adjust the sealing time, users can add more seconds to test whether the sealing is firm. If the vacuum sealer can't adjust the sealing time, users may need to replace the thinner bag or buy another vacuum sealer with setting sealing time function. (2)

There have also been cases where the bottom seal of the original bag was not sealed properly. In this case, seal the bottom sealing line again before vacuuming. 3. Vacuum bag styles are not suitable for vacuum sealers: non-nozzle vacuum sealers can't

be used for vacuum flat bags. Therefore, if you buy a non-nozzle vacuum sealer, you must pay attention to the style of the bag you use. This vacuum sealer is a must-to-use vacuum embossed bag or Nylon gusset vacuum bag. It is recommended that when purchasing

a vacuum sealing machine or vacuum bag, it is more appropriate to confirm with the supplier first. 4. The vacuum bag is broken: (1) If the package article has acute angles, be careful not to cut the vacuum bag when putting it into the vacuum bag. (2)

Vacuum sealer in the process of pumping, when the bag is shrunk to the package, it may be punctured by the packaging.

MORE

2024/11/5

What is Impulse Sealer Heating Element?

What is Impulse Sealer Heating Element? A Heating Element is a key component in impulse sealers, which are devices used to seal plastic bags and other thermoplastic materials. Here are the main points about this element: Function: The heating element

generates heat when an electrical current passes through it, which melts the thermoplastic material to create a seal. Material: The heating elements are typically made from a nichrome wire (an alloy of nickel and chromium) because of its high resistance

to electricity and ability to withstand high temperatures without breaking down. Operation: In impulse sealers, the heat is only generated when the sealer is in operation (i.e., when the handle is pressed down), which means the wire is only heated for short

periods. This helps prevent the wire from overheating and extends its lifespan. Replacement: Over time, the heating element can wear out due to repeated heating and cooling cycles. It may need to be replaced to maintain the sealer's effectiveness. Installation:

Replacing the heating element typically involves removing the old one, cleaning the sealing bar, and then carefully installing the new one to ensure it is taut and properly positioned. This component is crucial for the proper functioning of impulse sealers,

widely used in packaging industries to ensure seals.

MORE

.png)

.png)

.png)