Sealing length: 20cm.

Suitable material for kinds of plastic bags (PE, PP, OPP, PVC, OPF, NY), non-woven bag, thin alum. bags.

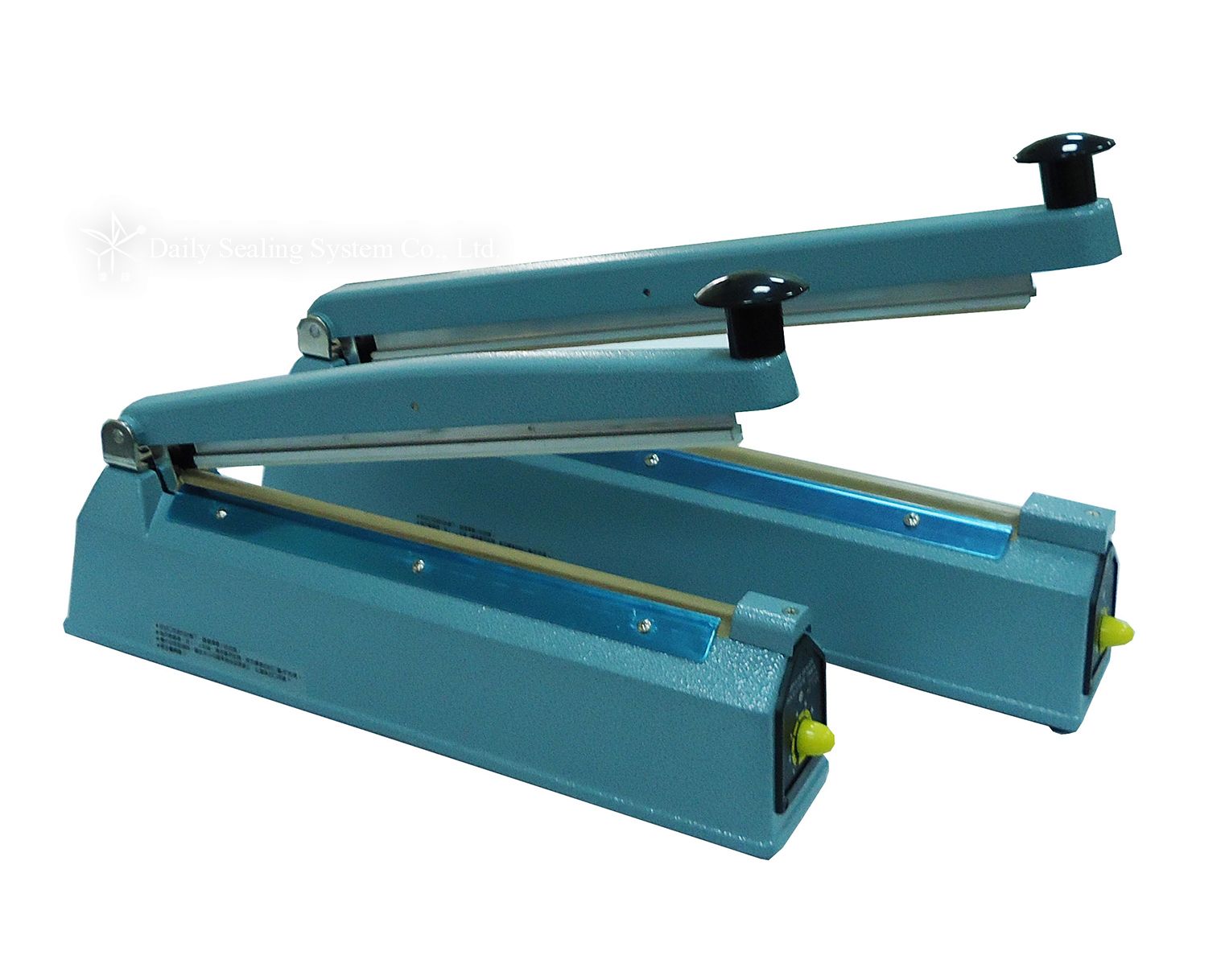

20cm Hand type impulse sealer:

• Machine: aluminum alloy with powder coating.

• Suitable material of bag: aluminum, tinfoil, sterilization bag, vacuum nylon bag.

| Model No. | DS-200H |

|---|---|

| Sealing type | Impulse Heat |

| Voltage/Ampere | 110V, 220V |

| Max.sealing | Max:200.0 x 2.0 mm |

| Machine weight | 2.50 kgs |

| Machine size | 320 x 80 x 215 mm |

| Sealing width | 2mm |

20cm Hand type impulse sealer: