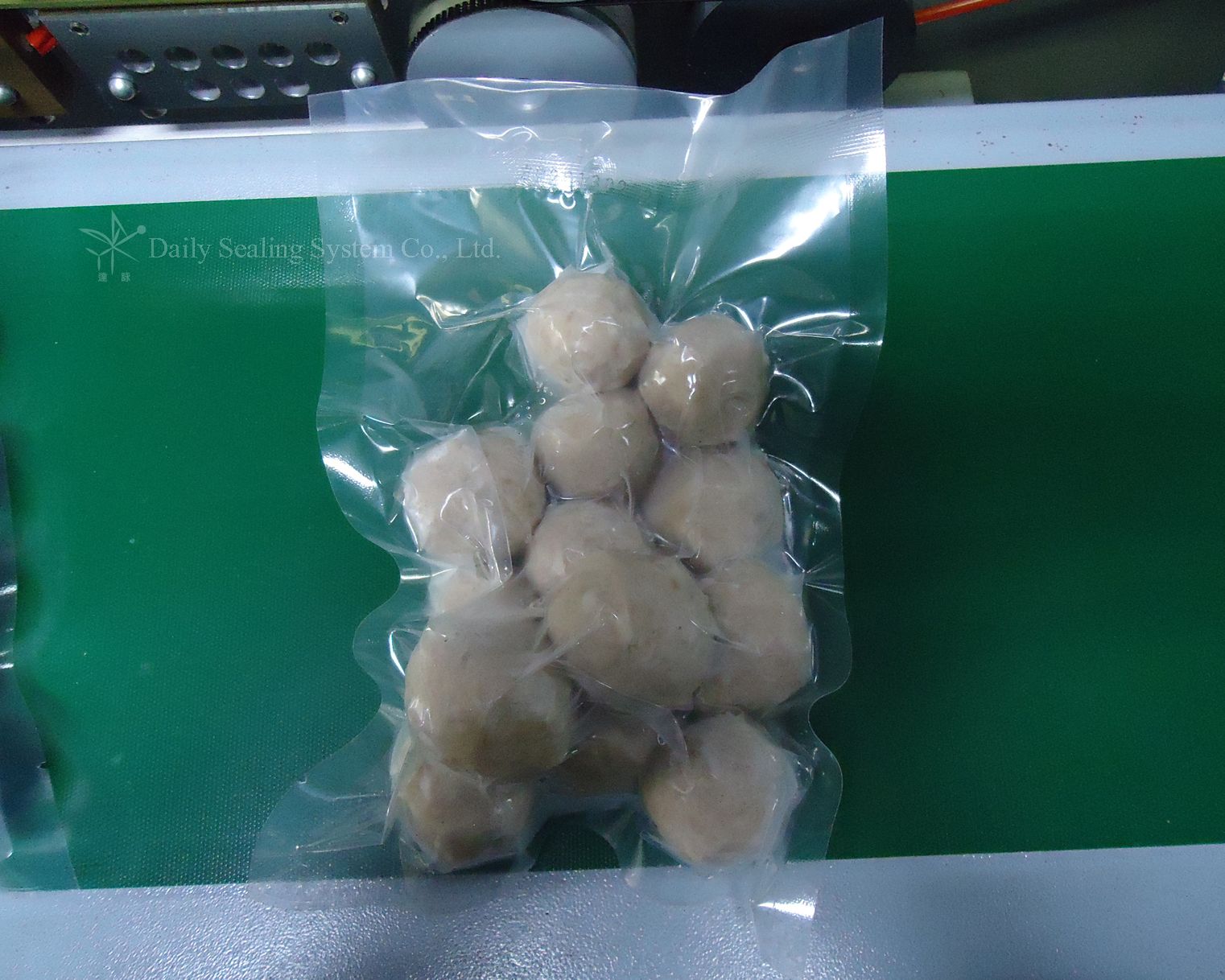

Vacuum degrees: 85%.

Suitable for packing products: meat, nuts, electronic component and part etc.

Vacuum degrees: 85%.

Suitable for packing products: meat, nuts, electronic component and part etc.

Horizontal nozzle vacuum band sealer:

• The sealing bar could be tilted down 0 - 20 degree.

• Outer housing: powder coating or stainless steel housing.

• Available for: foods, chemicals and hardware parts.

• Packing material: any kinds of heat sealable material.

• The length from bag seal to bag lid: max. L 45mm.

• Additional options:

Counter

Date coding machine

Gas extrusion (Nitrogen)

| Model No. | DPCV-903A |

|---|---|

| Voltage/Ampere | 1 phase 100V,110V,120V,220V,240V |

| Machine size | 1350 x 610 x 980-1160 mm |

| Sealing width | 5mm or 10mm |

| Sealing and conveyor speed | 0-10M/min(adjustable) |

| Bag total thickness | 0.26-0.50 mm |

| Bag size | 最大長 x寬: 300 x 300 mm |

| Conveyor width | 200mm |

| Conveyor height adjusting range | 130mm |

| Conveyor loading weight | 5 kgs |

| Packing | 1430 x 690 x 1130 mm |

Horizontal nozzle vacuum band sealer:

.jpg)