Sealing length: 35cm.

Operate mode: foot pedal switch controlled.

Need to connect air compressor.

Available for: aluminum foil bag, foil gusseted bag,tinfoil bag, vacuum nylon bag, cellophane bag.

Pneumatic pedal switch type constant heat sealer-double sealing

【Appearance Features】

• Uses painted steel plate, which is resistant to rust, safe and hygienic, designed for industrial use, and has improved durability.

• Can be made of stainless steel.

【Machine Features】

• Labor-saving, even force, low noise.

• Heating temperature can be adjusted according to the material and thickness of the packaging.

• Upper and lower heating to improve work efficiency.

• The object stop plate design can fix the sealing position, providing a beautiful and stable high-quality seal.

• Can count sealing times from 0 to 999.

• Users need to prepare their own air compressor (specifications 5~6 kgs/cm² or above), the foot switch starts the sealing, and the machine automatically seals according to the user's settings.

【Maintenance Method】

• No need for oil change maintenance.

Pneumatic pedal switch type constant heat sealer-double sealing Suitable for:

• Food processing industry: mixed grains, rice, corn, red beans, mung beans, soybeans, tea leaves, coffee beans, medicinal herbs, ginseng, Chinese medicinal packs.

• Electronic components, hardware parts, metal fittings.

Pneumatic pedal switch type constant heat sealer-double sealing Other options:

DC-350DR Pneumatic pedal switch type constant heat sealer

DS-300FD 30cm Foot type constant heat sealer

Pneumatic pedal switch type constant heat sealer-double sealing Suitable material of bag:

Aluminum foil bag, Foil gusseted bag, Tinfoil bag, Vacuum nylon bag, Cellophane bag.

Pneumatic pedal switch type constant heat sealer-double sealing FAQs:

Q: What types of bags are suitable for pneumatic direct heat sealing machines?

A: Suitable bags include aluminum foil bags, tin foil bags, KOP bags, sterilization bags, and vacuum NY bags.

Q: What is the function of the red light on a pneumatic direct heat sealing machine?

A: It is for preheating. Adjusting the temperature requires some time to wait. When the red light is on, it indicates heating, and when it goes off, it means the set temperature has been reached.

Q: How long should one wait before using it during heating?

A: You can use it after the red light goes off.

Q: How to test the suitable temperature for bags?

A: Different bag materials require different temperatures. It is recommended to start testing from a low temperature and increase it if necessary.

Q: Why do bags dissolve?

A: It indicates that the temperature is too high and needs to be lowered.

Q: Why is the sealing line of the bag incomplete?

A: It indicates that the temperature is not high enough and needs to be increased.

Q: Why can't PE and PP bags be used?

A: Because the bags will stick to the sealing bar, causing residue on the sealing bar that cannot be cleaned.

| Model No. | DC-350DRT |

|---|---|

| Sealing type | Constant Heat |

| Voltage/Ampere | 110V /220V |

| Power | 110V 550W |

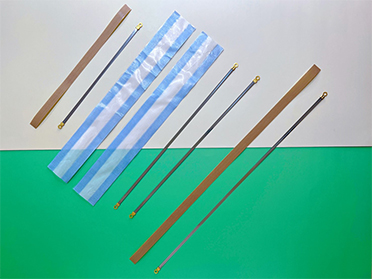

| Max.sealing | 350*10mm(The teflon coating on sealing bar) |

| Machine weight | 11 kg |

| Machine size | 410x305x310mm |

| Sealing Temperate | 90 - 250℃ |

| Machine material | Steel plate with powder coating |

| Suitable material of bag | Aluminum foil bag, Foil gusseted bag, Tinfoil bag, Vacuum nylon bag, Cellophane bag. |

| Suitable for packing products | Food, Electronic Component, Hardware Parts etc. |

| Warranty | 1-year guarantee |

| Origin | Taiwan |