L type sealing line.

Controlled by foot pedal switch.

Need to connect air compressor.

L type sealing line.

Controlled by foot pedal switch.

Need to connect air compressor.

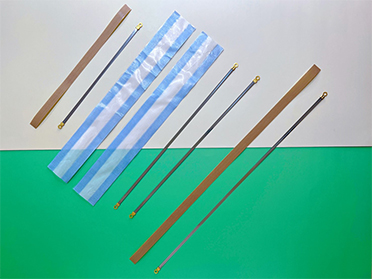

Pneumatic irregular shape sealer:

• Made in Taiwan.

• As per package material and degree of thickness to adjust increasing the sealing time and cooling time for good sealing quality steadily.

• Pneumatic pedal switch control: easy operation, gives consistent and trim result every time.

• Available for: PE, PP, OPP, PVC, POF, NY, antiseptic bag....etc.

• Options:

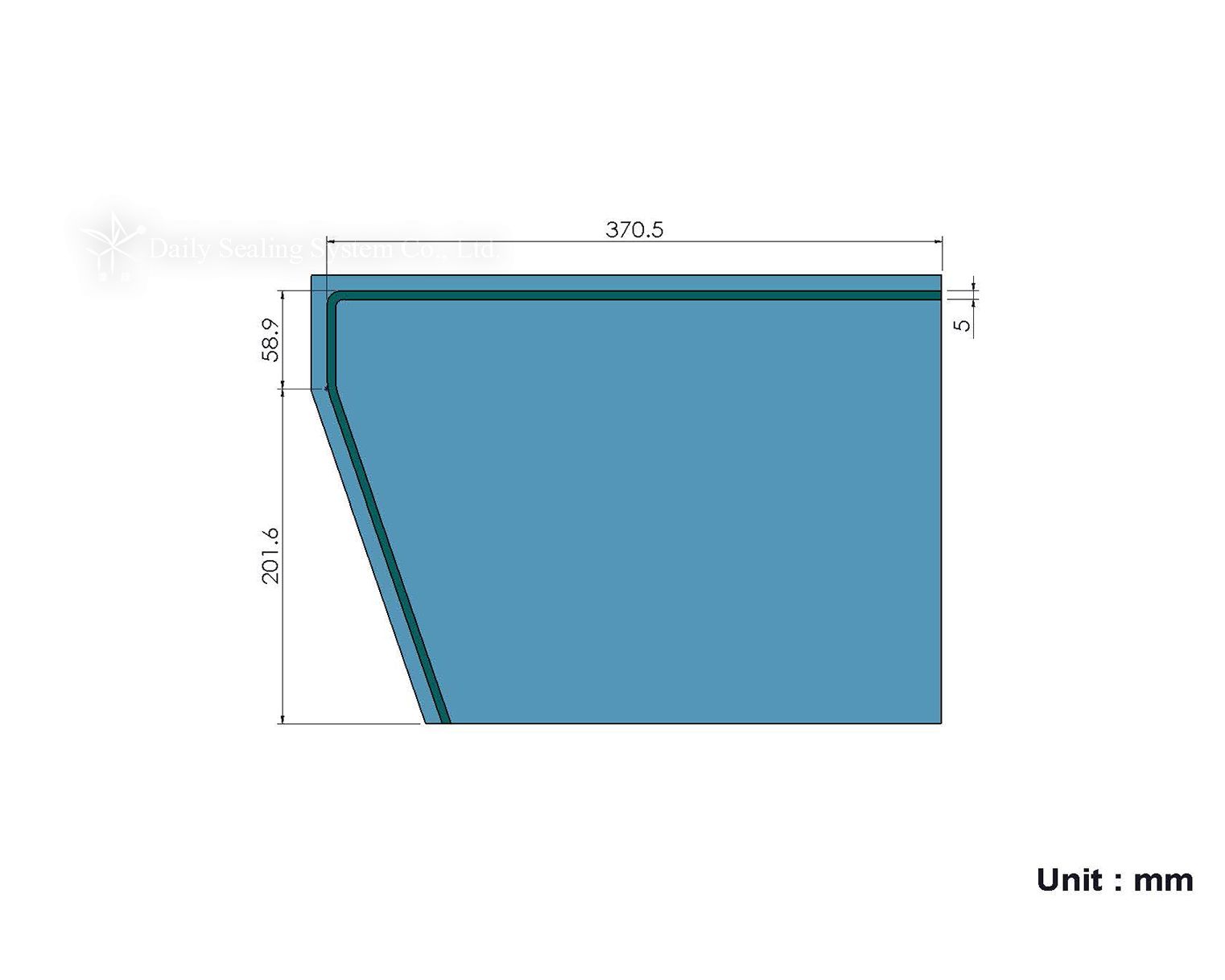

(1) Changeable the shape of sealing which depends on customer demands.

(2) Size of heating element: 2.7mm, 5mm or 10mm.

(3) Sealing time: it could adjusted the sealing time which depends on customer demands.

| Model No. | DTC4-650L |

|---|---|

| Sealing type | Impulse Heat |

| Voltage/Ampere | 110V / 10.8A,220V / 5.9A |

| Power | 1300W |

| Max.sealing | Max:700.0 x 5.0 mm |

| Sealing time | 0.0–1.5 sec. |

| Cooling time | 0.0–10.0 sec. |

| Machine weight | 42.00 kgs |

| Machine size | 658 x 500 x 459 mm |