Sealing length: 35cm.

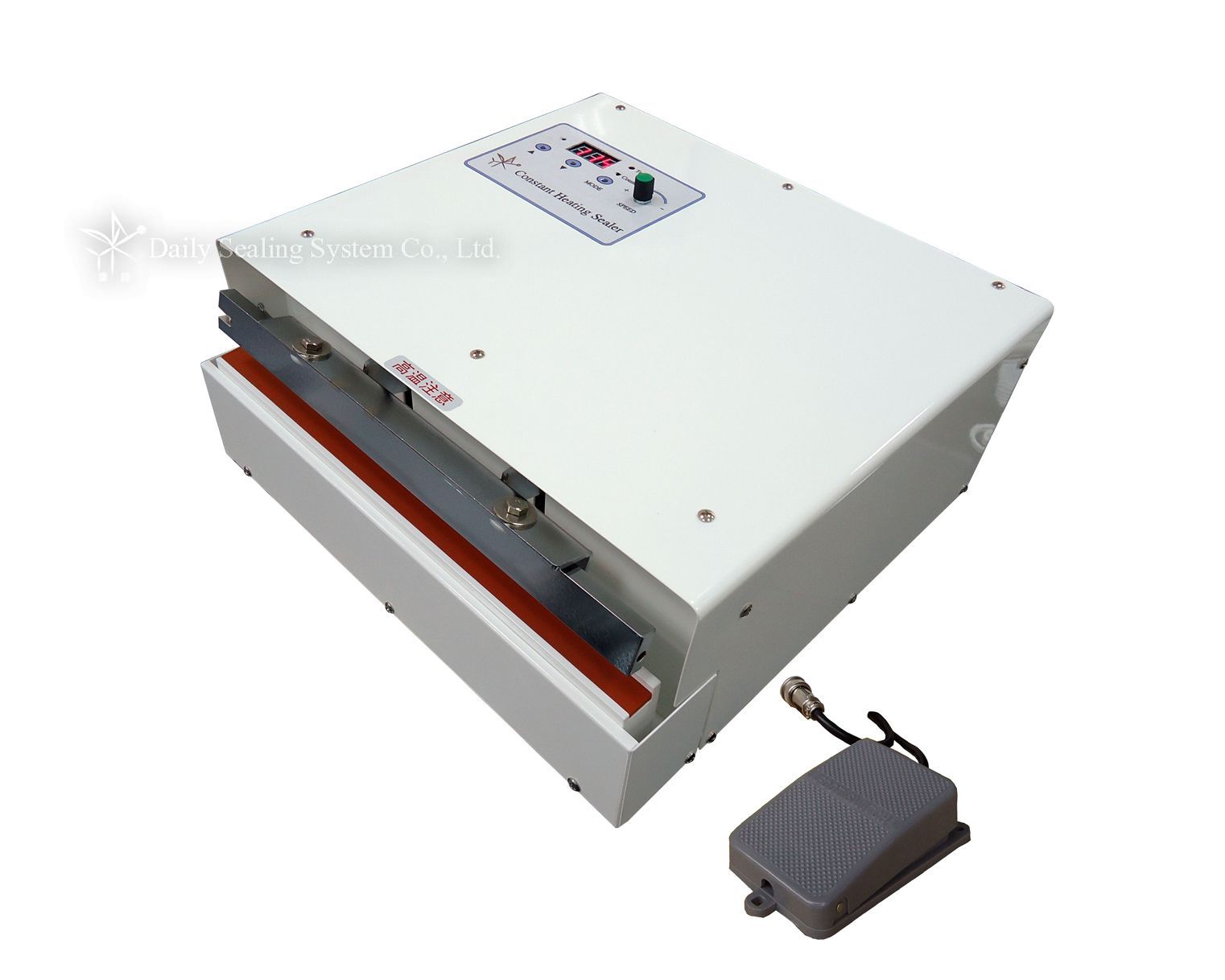

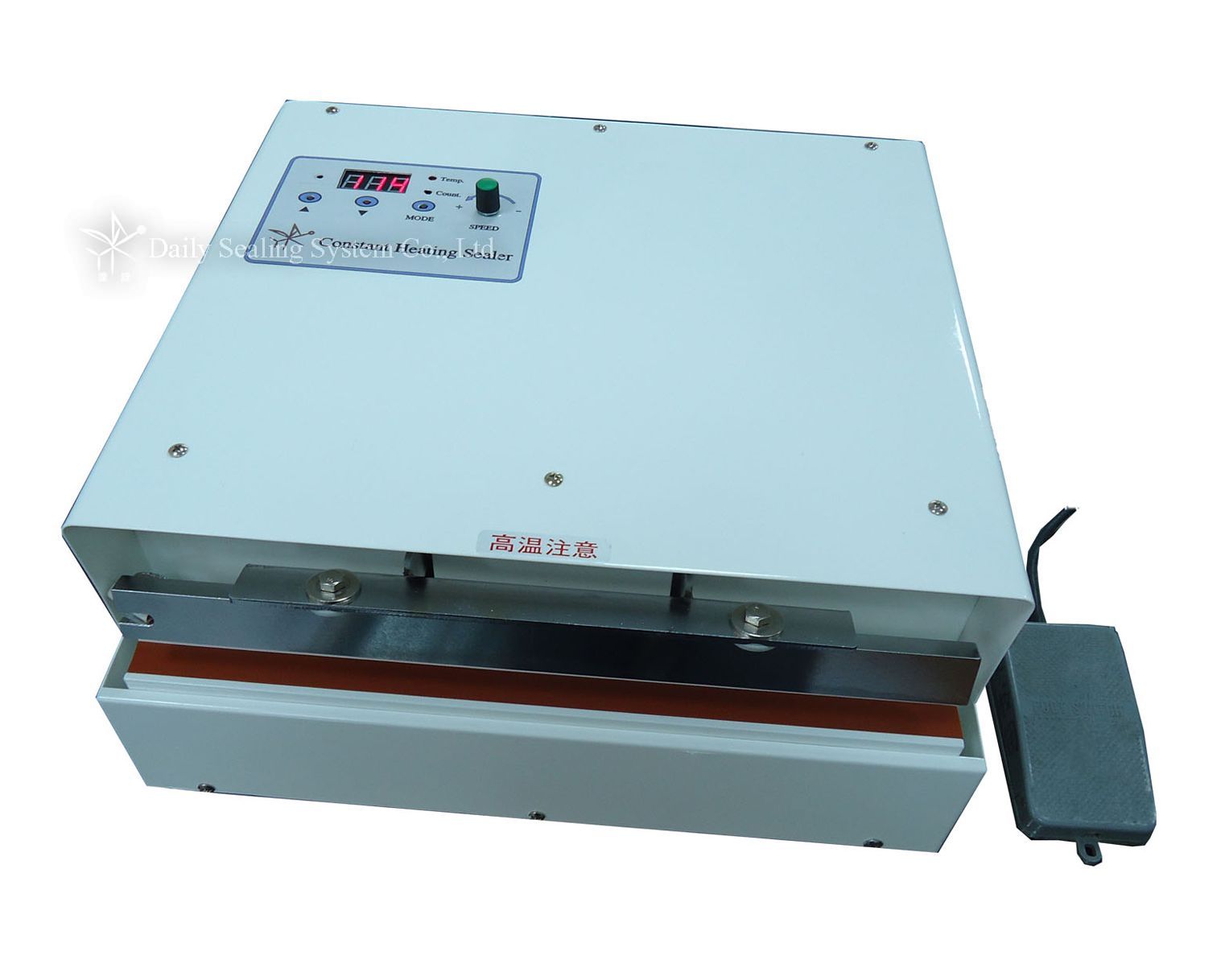

Operate mode: foot pedal switch controlled.

Available for: aluminum foil bag, tinfoil bag, vacuum nylon bag, cellophane bag.

Sealing length: 35cm.

Operate mode: foot pedal switch controlled.

Available for: aluminum foil bag, tinfoil bag, vacuum nylon bag, cellophane bag.

Pedal switch controlled constant heat sealer:

• Made in Taiwan.

• Machine: made of metal plate coating, keeps hygiene and safety.

• Heating line: offering mesh or straight-line texture.

• Temperature control: Thermostatic control, as per package material and degree of thickness to adjust increasing temperature for good sealing quality steadily.

• Including the counting device, which can count the finished seals automatically and pre-set the desirous sealing times (0-999) for the same.

• Motor control: fixing sealing pressure, gives consistent and trim result every time.

• This machine is mini size which can save space and move easily.

• Available for: aluminum, tinfoil, KOP, antiseptic bag, vacuum nylon bag

| Model No. | DM-350DR |

|---|---|

| Sealing type | Constant Heat |

| Voltage/Ampere | 110V / 4A,220V |

| Power | 450W(110V) |

| Max.sealing | Max:350.0 x 10.0 mm |

| Sealing time | adjustable |

| Machine weight | 15.60 kgs |

| Machine size | 385 x 382 x 205 mm |

| Sealing Temperate | 90 - 250℃ |

| Warm up time | 5- 10 mins |

Pedal switch controlled constant heat sealer:

.jpg)