Made in Taiwan. UL certification.

.jpg)

- Detail

Solenoid Valve:

• UL certification

• Spec:

|

Input terminal: Rated current: 115V 50/60 HZ Exciting current: 150 mA Normal rated power: 10 VA Resistance: 630Ω±15% |

|

|

Anti pressure test |

0.6 KV 60 SEC 10 Ma |

|

Orifice |

2.0mm |

|

Port Size |

Ø10 |

|

Working pressure |

0-0.4 Mpa |

|

Operation Temperature |

0-60℃ (When not frozen) |

|

Temperature class of |

class A |

|

Material of valve body |

PBT |

|

Size |

20.4*20*27.8mm |

Specification

You May Also Like

Why Choosing Dailysealing

Parts and material quality control

- Heating elements are from Japan.

- Motor, Transformers, PCB and vacuum bags are made in Taiwan.

Strict quality control

- 100% product inspection: The inspection is included functions and appearance of sealing machines.

- Tensile strength test to ensure the sealing line tensile strength value reaches the customer standard.

- Electric leakage test: Puncture and insulation test.

- Our production and inspection are all based on ISO 9001.

Professional packaging and sealing machine factory

- Produce many kinds sealing machines and ODM/OEM products and provide custom-made services.

- More than 30 year experiences in packaging machines industry.

- Sell sealing machines to America, Europe, Latin America and Asia.

- 85% products in stocks, so we can deliver the products quickly.

- The production process is based on SOP to ensure the quality of sealing machines consistently.

Complete range of specifications of sealing machines

- Complete range of specifications of sealing machines.

- Many kinds of sealing machines and consumptive materials in stocks, so customers can do one-stop shopping here.

- The customers include Biotechnology companies, Medical equipment companies, Food industry, Electronics industry, Handmade soap industry and other industry..

Custom-made sealing machine service

- Custom-made sealing machine service

- Designs of the special sealing machine for irregular shape sealing line, such as U-shape sealing line and L-shape sealing line.

- Different width of sealing line could be custom-made to meet customer requirements.

After-sales service of professional sealing machine

- Provide the professional service for repair the broken sealing machine immediately.

- The sufficient supply of parts stock, so don’t worry about the parts replace.

- Some parts of sealing machine are used in common specifications, so it is easy to get the parts for replace.

Exhibitions and trade shows

News

.png)

2024/6/21

FAQs (Frequently Asked Questions) about vacuum packaging

FAQs (Frequently Asked Questions) about vacuum packaging Vacuum packaging is currently a trend, and recently, many users have purchased vacuum sealers or vacuum bags, generating a lot of questions. Here are answers to the most commonly asked questions:

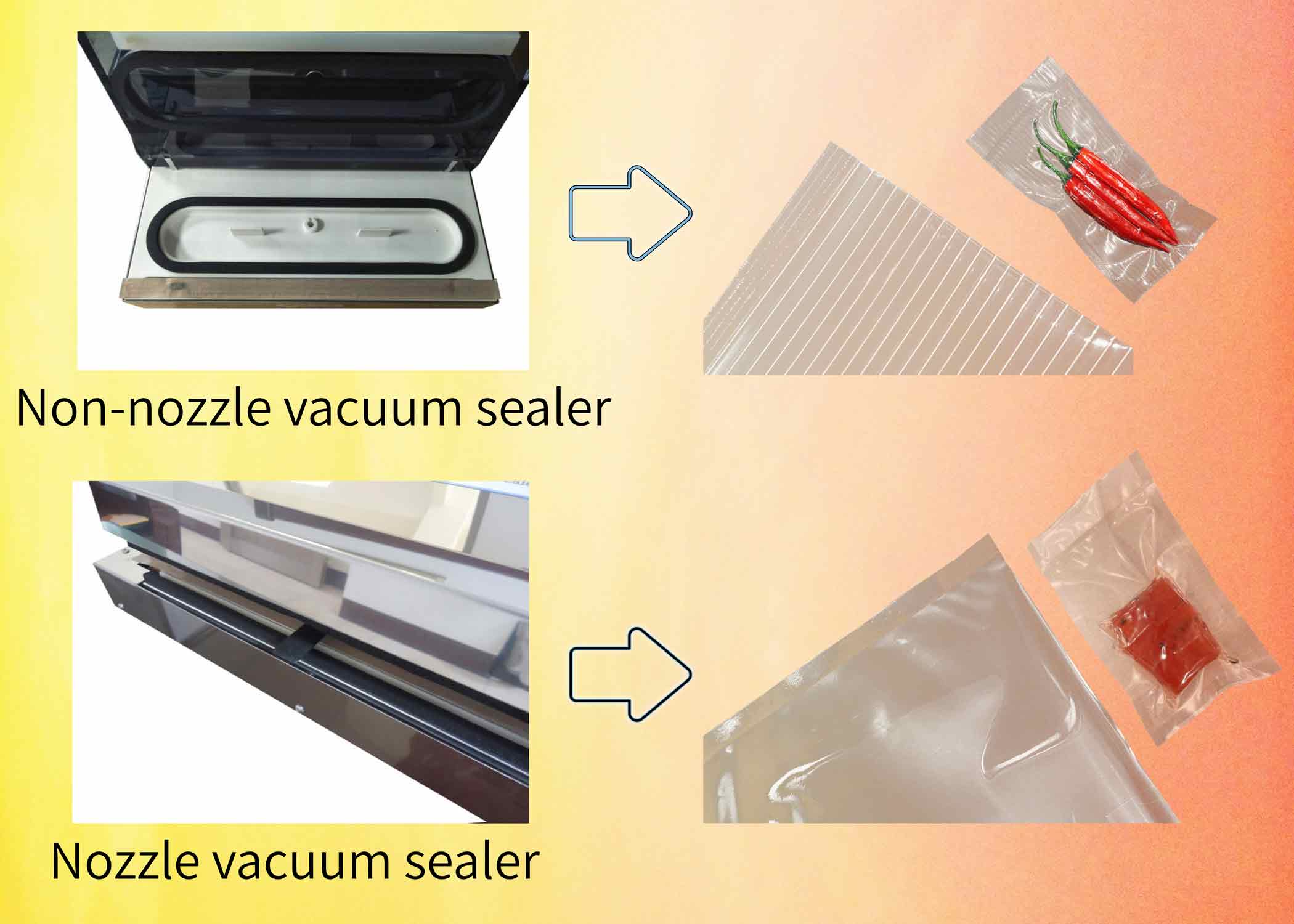

1. Which vacuum sealer is suitable for me? A: There are many vacuum sealers on the market, and it is not easy to choose a suitable vacuum sealer. I have previously written about "How to Choose a Vacuum Sealer". Those with questions can refer to it for

getting more information. "How to choose a vacuum sealing machine", please check the following website address. *Nozzle type vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1116 *Non-nozzle type vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1115

*Chamber vacuum sealer: https://www.dailysealing.com/news_detail.aspx?seq=1114 2. Why can't I use PE bags for vacuum packaging? A: Due to the density of the bag material. Even after air is removed and sealed, air can still seep back into the bag. Therefore,

after packaging, if left alone for a period of time, the vacuum effect will be lost. 3. What type of bag material is suitable for vacuum packaging? A: The most common vacuum bag materials are nylon (NY) bags and aluminum foil bags. Both of these materials

can prevent air from seeping back into the bag and maintain a vacuum state inside the bag. 4. Why can't I maintain a vacuum effect even after using vacuum bags? A: If you have confirmed that you are using vacuum bags, you can first check if the seal

is defective. Some vacuum bags are too thick and require a longer sealing time, such as foldable bags (tea bags), which have four layers. If the seal is confirmed to be perfect, check if there are any holes in the vacuum bag. When vacuuming, the bag will adhere

closely to the contents. If the contents have sharp edges, it is possible to puncture the bag and lose the vacuum effect. 5. Many users who have bought vacuum sealers or vacuum bags are confused when they find that they can't remove the air from flat

vacuum bags. What should they do? A: This is because they have purchased a vacuum sealer without a nozzle. The non-nozzle type vacuum sealers have to use the special vacuum bags (channel bags, embossed bags and gusset bags) to remove air, so if users use flat

vacuum bags, they will find the vacuum sealer and vacuum bag can't work. 6. If someone accidentally purchases a non-nozzle vacuum sealer (such as FOODSAVER), what types of vacuum bags can they use? A: The following types of vacuum bags can be used:

(1) Vacuum sealer embossed bags (vacuum channel sealer bags): vacuum bags with straight stripes. (2) Fold-over bags: such as tea bags with two sides folded in to become a four-layer bag. (3) Back-sealed bags: vacuum bags with one side flat and the

other side with an additional spine. Remember to choose aluminum foil bags and nylon bags as the material for vacuum bags. 7. What is the difference between a vacuum flat bag and a vacuum striped channel sealer bag? A: A vacuum flat bag is like a regular

plastic bag with both sides being flat are smooth, but the material of a vacuum flat bag is made of nylon (NY) or aluminum foil. A vacuum channel sealer bag has one flat smooth side and the other side has straight stripes. 8. Why can a vacuum channel

sealer bag be used with a Non-nozzle vacuum sealer? A: The key is in the straight stripes of the vacuum channel bag. The structure of a Non-nozzle vacuum sealer requires a straight stripe to create a channel for the air inside the bag to be removed. If the

stripes are too shallow, it may still be unable to vacuum out the air.

MORE

2025/12/24

Vacuum Sealer Bags 101: Can I Reuse Them & What Bags Work with My Machine? (Vacuum Sealer

Vacuum Sealer Bags 101: Can I Reuse Them & What Bags Work with My Machine? (Vacuum Sealer Bags, Consumables) The bags you use are the most important consumables for your vacuum sealer. Understanding the different types and reuse rules can save you money

and ensure a perfect seal every time. Can I Reuse Vacuum Sealer Bags? The short answer is yes, sometimes, but with a big safety caveat. When to Reuse: If the bag contained clean, low-odor, cooked, or dry foods (like baked goods, nuts, or leftover pasta),

you can often wash, dry, and reuse the bag. Just make sure to cut the original seal cleanly and ensure the bag is completely dry before re-sealing. When NOT to Reuse (Safety First): Never reuse bags that have contained raw meat, poultry, fish, or greasy/oily

foods. Even after washing, there is a risk of cross-contamination and the residue may compromise the next seal. When in doubt, use a new bag. Which Bag Type Do You Need? The type of bag you buy depends entirely on the type of vacuum sealer you own: Vacuum

sealer embossed and channel bags (For non-nozzle type vacuum sealer): non-nozzle type vacuum sealer (the most common type, where the bag sits outside the machine) require bags with a special texture or channels inside. This texture allows the air to be successfully

drawn out of the bag and past the sealing area. Smooth Bags (For Nozzle Type Vacuum Sealer and Chamber Vacuum Sealers): Chamber vacuum sealers work by removing all air from a chamber where the bag is fully enclosed. Because of this, they can use more economical

smooth bags that lack the internal texture. Make sure you are purchasing the correct vacuum sealer bags for your machine, as using a smooth bag in a non-nozzle type vacuum sealer will result in a complete vacuum failure.

MORE

2024/12/24

How a Vacuum Sealer Works

How a Vacuum Sealer Works Many friends often ask: "Do I have to use a vacuum bag when using a vacuum sealer?" "Do I have to use special bags when using a vacuum sealer? Can I use flat vacuum bags with non-nozzle type vacuum sealers? Can I use all type

vacuum bags with chamber vacuum sealers?" You can find the answer after reading the following instructions. 1. Do we have to use vacuum bags for vacuuming? A: If you only want to remove air, any material can be used. But if you want to maintain the vacuum

state for a long time, you must use vacuum bags which are PA (Nylon) material or aluminum foil bags with high airtightness. 2.Does "vacuum" really mean making the bag completely free of gas inside? A: Actually not, the main principle is to reduce the air

inside the bag to a level where microorganisms cannot survive, reducing oxidation or product spoilage, keeping items less susceptible to rusting, and maintaining the freshness and shelf life of food inside the bag. 3.Differences in principles between Non-nozzle

vacuum sealer and chamber vacuum sealer. A: There are two different principles of air extraction, which also lead to different advantages and disadvantages. (1) Non-nozzle vacuum sealer: Directly extract the air from the bag, and then use heating to melt and

seal the plastic bag. Therefore, if you want to package fluids or powders, Non-nozzle vacuum sealers are likely to extract the contents you want to package, or extract contents that should contain moisture. Sometimes it may even cause internal parts to get

wet and be damaged. Most of the vacuum bags seen on the market have patterns on them, which is because most vacuum sealing machines are direct air suction type. When sealing wet items with this type of vacuum packaging machine, it is necessary to form channels

for smooth air. These channels are the patterns or folds on the vacuum bags or aluminum foil bags commonly seen in the market. When the air in the bag is reduced, aerobic bacteria cannot survive, so the items can be preserved for a longer period of time. Therefore,

whether it is a grid pattern, diamond pattern, or the vacuum channel sealer bags made by our company, they are all designed to facilitate air flow. Therefore, we would recommend using non-nozzle vacuum sealers for items with less water content and larger particles

inside. (2) Chamber vacuum sealer: When the lid is closed, the motor begins to perform the vacuuming action. At this time, the air inside the vacuum chamber and inside the vacuum bag will be affected by the motor and flow, so the pressure inside the vacuum

chamber will gradually become negative pressure. At this time, we may observe a phenomenon where the vacuum bag we placed inside is expanded. This is because the speed at which the air is removed from the vacuum bag cannot be as fast as that in the vacuum

chamber, which causes the pressure inside the bag to be greater than other parts of the vacuum chamber in a short time. This phenomenon will also cause the air inside the bag to accelerate and leave the bag at the moment the solenoid valve operates, and at

the same time, the heating plate will heat and seal the bag. Since it does not directly vacuum the air out of the bag, there is no need to worry about the moisture inside the bag being drawn out. For items with liquid or powder content, we would recommend

using a chamber vacuum sealer. Because the air inside the vacuum chamber is vacuumed out, the bag does not need an additional air extraction duct, so it can be used without embossed vacuum bags. 表單的頂端 表單的底部表單的頂端

MORE

(1).jpg)